I-Laser Maintenance Guide Ngemva Kwamaholide

Isikhathi sokungasebenzi kwemishini ye-laser ngokuvamile siba side ngamaholide. Ukukusiza ukuthi uqalise kabusha umsebenzi ngokushesha nangokushelela, silungiselele ngokucophelela umhlahlandlela wokuqalisa kabusha i-laser ukukusiza ukuthi uqalise!

Isikhumbuzi esifudumele: Uma isihlanganisi sinemiyalo enemininingwane eyengeziwe, lo myalelo ungasetshenziswa njengefayela eliyireferensi futhi usetshenziswe ngokufanele.

Isinyathelo 1: Izokuphepha zibalulekile

1. Cisha ugesi bese uvala amanzi

(1) Ukuze kuqinisekiswe ukuphepha kwabasebenzi kanye nezinto zokusebenza, qinisekisa ukuthi ukuphakelwa kukagesi kwesistimu ye-laser kanye nesipholile samanzi kuvaliwe;

(2) Vala wonke ama-valve angenisa amanzi kanye nama-valve okukhipha amanzi esipholisa amanzi.

Amathiphu: Ungakhombi amehlo akho ngqo lapho kuphuma khona i-laser nganoma yisiphi isikhathi.

Isinyathelo sesibili: ukuhlolwa nokugcinwa kwesistimu

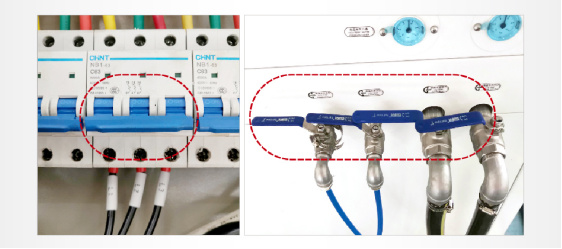

1. Uhlelo lokuhlinzeka ngogesi

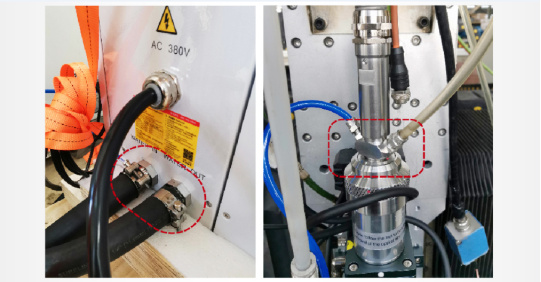

(1) Ulayini wokuphakelwa kukagesi: akukho ukugoba okubi kakhulu, akukho monakalo, akukho ukunqanyulwa;

(2) Ukuxhumeka kwentambo yamandla: cindezela ipulaki ukuze uqinisekise uxhumano oluqinile;

(3) Ikhebula lesignali yokulawula: I-interface ixhunywe ngokuqinile ngaphandle kokuxega.

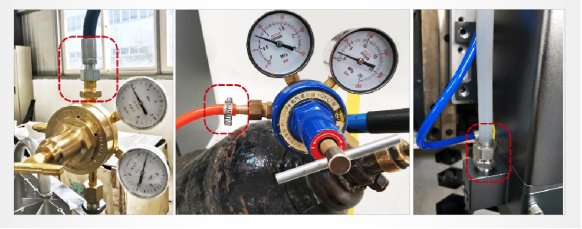

2. Uhlelo lokuhlinzeka ngegesi

(1) Ipayipi legesi: akukho monakalo, akukho ukuvaleka, ukungangeni kahle komoya;

(2) Qinisa amalunga amapayipi egesi ukuze uqinisekise ukuxhumana okuqinile nokushelelayo;

(3) Sebenzisa igesi ehlangabezana nezindinganiso ngokwezidingo zomkhiqizi wezinsimbi.

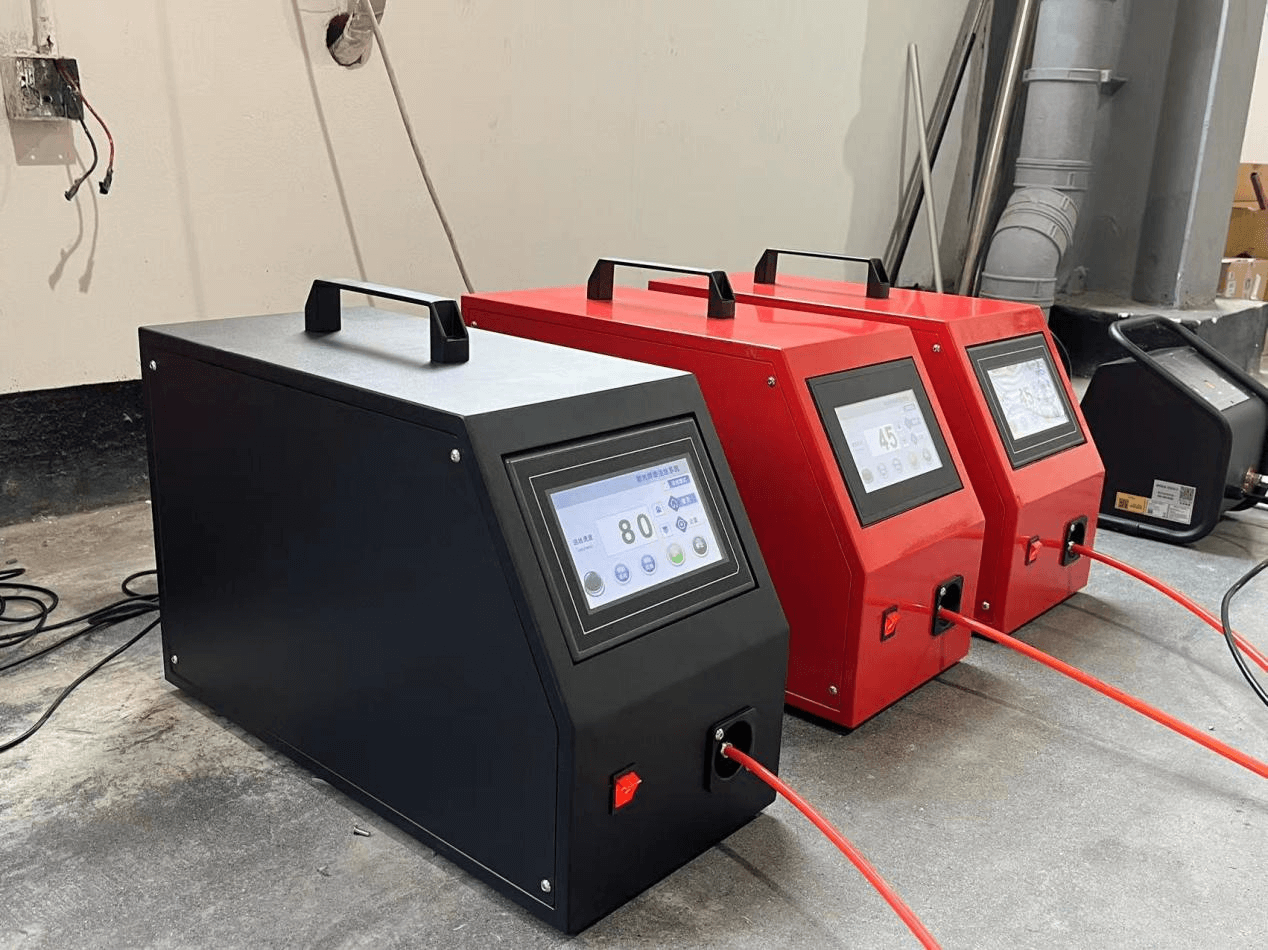

3. Uhlelo lokupholisa amanzi

(1) Qinisekisa futhi ukuthi ama-valve okungenisa kanye nawokuphuma avaliwe;

(2) Ithangi lamanzi / ipayipi lamanzi: akukho ukugoba, akukho ukuvaleka, akukho monakalo, ipayipi lamanzi lethangi lamanzi liyahlanzwa;

(3) Qinisa amapayipi amanzi ukuze uqinisekise ukuxhuma okuqinile nokushelelayo;

(4) Uma izinga lokushisa lomoya lingaphansi kuka-5 ℃, udinga ukusebenzisa okokusebenza komoya ofudumele ukuze ushaye amapayipi angaphakathi esipholile samanzi isikhathi esithile ukuze uqinisekise ukuthi akukho ukuqandisa;

Amacebiso: Uma okokusebenza kuvalwe isikhathi eside endaweni engaphansi kuka-0 ℃, udinga ukuhlola ngokucophelela ukuthi ipayipi lamanzi okupholisa lineqhwa noma izimpawu zokuma kweqhwa.

(5) Faka inani elinqunyiwe lamanzi acwebile emshinini wokupholisa amanzi bese uwayeka ume imizuzu engama-30 ukuqinisekisa ukuthi azikho izimpawu zokuvuza kwamanzi;

Amacebiso: Uma izinga lokushisa lingaphansi kuka-5 ℃, udinga ukulihlanza ngendlela efanele bese wengeza i-antifreeze.

(6) Vula inkinobho yamandla epholile amanzi, futhi ugcine amandla ezinye izinto zokusebenza evaliwe;

(7) Vula ama-valve okungenisa nokukhipha amanzi kancane, bese ugijima isipholile samanzi ukuze ujikelezise amanzi okupholisa esuka ku-laser kanye nekhanda elikhanyayo uwayise ethangini lamanzi ngesilinganiso esiphansi sokugeleza, futhi ukhiphe umoya oweqile ipayipi lesifunda samanzi. Le nqubo inconywa ukuba igcwaliswe phakathi kwe-1min;

(8) Maka indawo yezinga lamanzi ethangini lamanzi, uliyeke lime imizuzu engama-30 futhi, ubheke ukuthi alukho yini ushintsho ezingeni lamanzi, futhi uqinisekise ukuthi akukho ukuvuza epayipini langaphakathi;

(9) Uma ingekho inkinga ekuqinisekiseni okungenhla, qala kabusha isipholile samanzi, futhi uvule ivalvu yamanzi ngokujwayelekile, ulinde izinga lokushisa lamanzi lifinyelele izinga lokushisa elibekiwe, futhi ulungiselele ukusebenza kwempahla.

Isinyathelo sesithathu: ukutholwa kokusebenza kwemishini

1. Idivayisi ivuliwe

(1) Qinisekisa ukuthi izinga lokushisa lamanzi le-cooler yamanzi selifinyelele izinga lokushisa elibekiwe;

Amathiphu: Isivinini sokukhuphuka kwezinga lokushisa kwamanzi sihlobene nokuthi isipholile samanzi sinomsebenzi wokushisisa.

(2) Vula inkinobho yamandla yesistimu yokucubungula i-laser. Ngemuva kokuthi i-laser ivuliwe, isibonisi saMANDLA kuphaneli ye-laser sizokhanya.

Amathiphu: Hlola i-optical circuit kuqala, ungakhiphi ukukhanya noma ucubungule isikhashana. Ngemuva kokuthi i-laser isiqalile, bheka ukuthi izinkomba zijwayelekile yini nokuthi ikhona yini i-alamu. Uma kune-alamu, ungaxhuma isofthiwe yokuqapha nge-laser ukuze ubuke imininingwane ye-alamu futhi uxhumane nomphakeli wemishini!

2. Ukutholwa ngaphambi kokukhipha ukukhanya

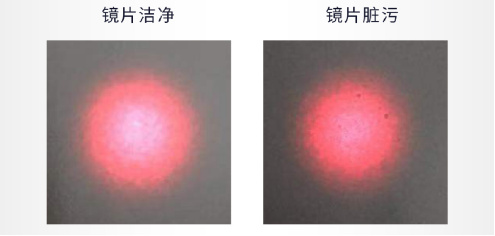

(1) Khetha indlela yokuthola ukukhanya okubomvu ukuze uhlole ukuhlanzeka kwelensi

Kwesobunxele: Hlanza / Kwesokudla: Okungcolile

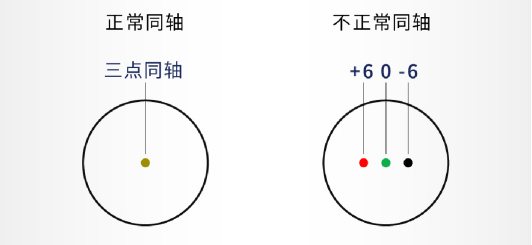

(2) Ukuhlolwa kwe-coaxial: yahlulela ukuhlangana kwembobo ye-nozzle kanye ne-laser beam ngokwezinga elilandelayo.

Imiphumela yokuhlolwa: Akukho okungavamile.

Kwesobunxele: Okuvamile / Kwesokudla: Okungavamile

Uma kwenzeka isimo esingavamile, ungalungisa indawo ye-laser beam ngokuzungezisa isikulufu ngosizo lukakhiye we-hexagon. Bese uhlola indawo ye-laser beam kuze kube yilapho amaphuzu okugxilwe kuwo esedlulene.

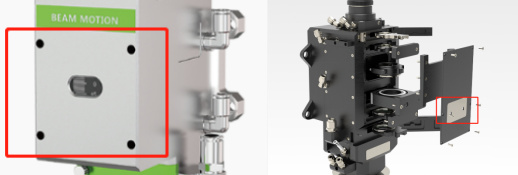

Kwesobunxele: Raytools/Kwesokudla: Boci