Inkampani ye-Electronics ye-Shanghai Bochu isungula iNkqubo yamva nje: I-TubesT_V1.51 ekupheleni kukaJanuwari ka-2024

I-Shanghai Bochu Electronics Inkampani ibhengeze ukukhutshwa kwenkqubo yayo yamva nje, i-TubesT_V1.51, ekupheleni kukaJanuwari 2024. Le nkqubo ibonelela ngendlela efanelekileyo yokudweba iparameterized for staircase, railing, and handrail industry. Ixhasa ukuveliswa okukhawulezayo kwamacandelo afana nemivalo ethe tye, iikholomu, imivalo ethe nkqo, kunye nemibhobho engaphezulu enesetyhula okanye amacandelo etyhubhu yesikwere. Ikwabonelela ngeendlela ezahlukeneyo zokuhlanganisa, kubandakanya "ukumakishwa kwe-welding" okanye "indibano yokufaka."

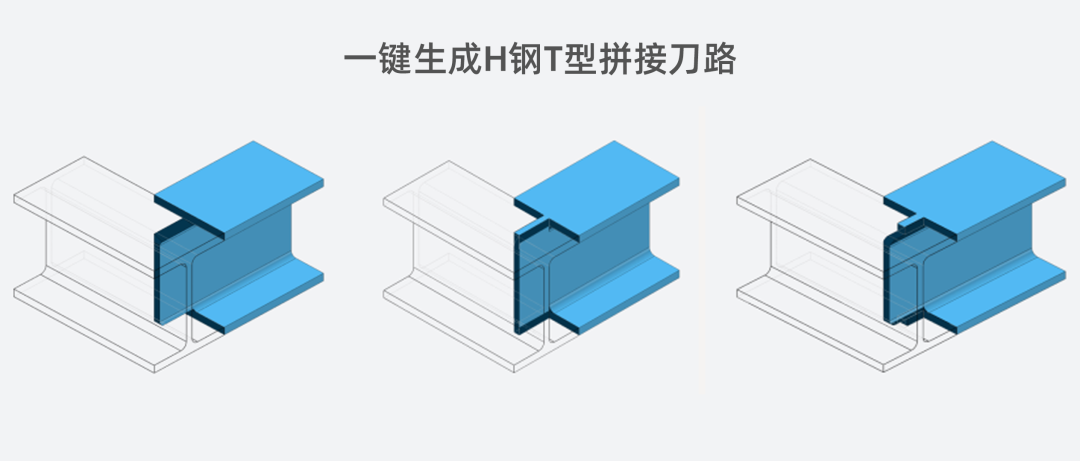

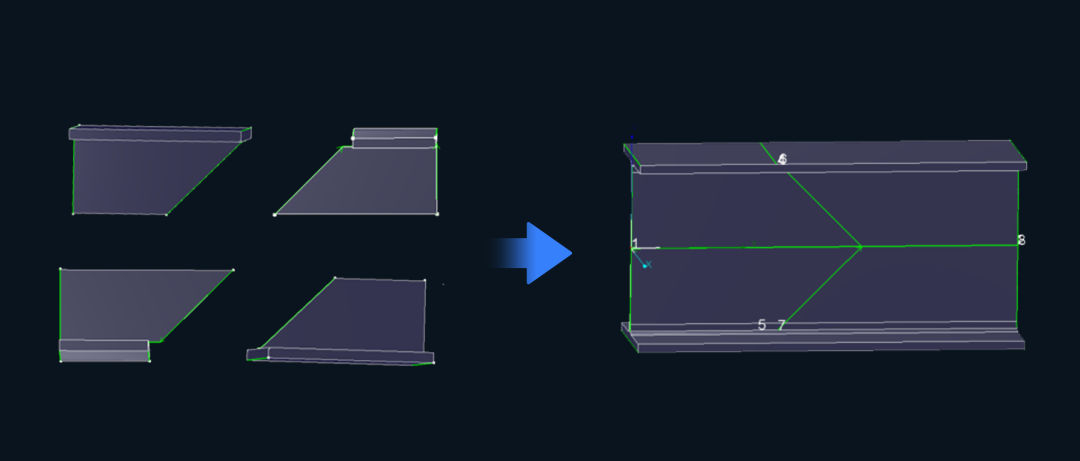

Inkqubo entsha iphinde ixhase ukuveliswa ngokuzenzekelayo kweendlela ezahlukeneyo ze-H-beam / I-beam T-joint cut. Kwi-H-beam (okanye i-I-beam) amacandelo afuna uxhulumaniso lwe-T-joint, inkqubo yazisa umsebenzi wokucofa okukodwa ukuvelisa indlela yokusika i-T. Oku akugcini nje ukusindisa ixesha kwimizobo yezandla kunye nokusetyenzwa kodwa kukwaphucula ukusebenza kakuhle kwemveliso kunye nokusebenza.

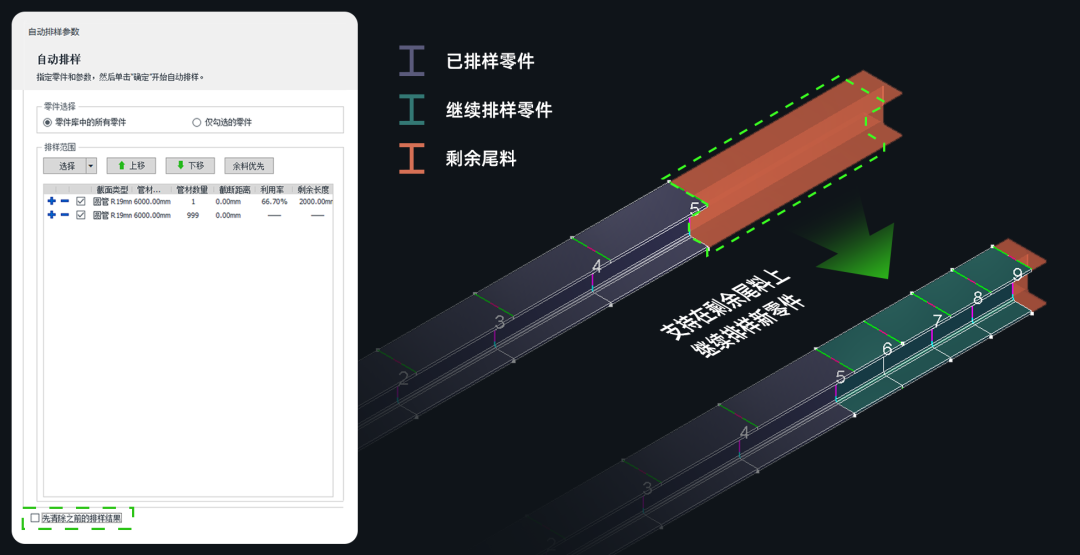

Ukuqhuba indlwane ngoku kuyafumaneka kwindawo yokuzenzela indlwane. Xa inketho "ecacileyo yeziphumo zendlwane yangaphambili" ingakhethwanga, abasebenzisi banokuqhubeka nokuzalela ngokusekelwe kwiziphumo ezikhoyo, ngaloo ndlela bephucula ukusetyenziswa kwezinto zombhobho.

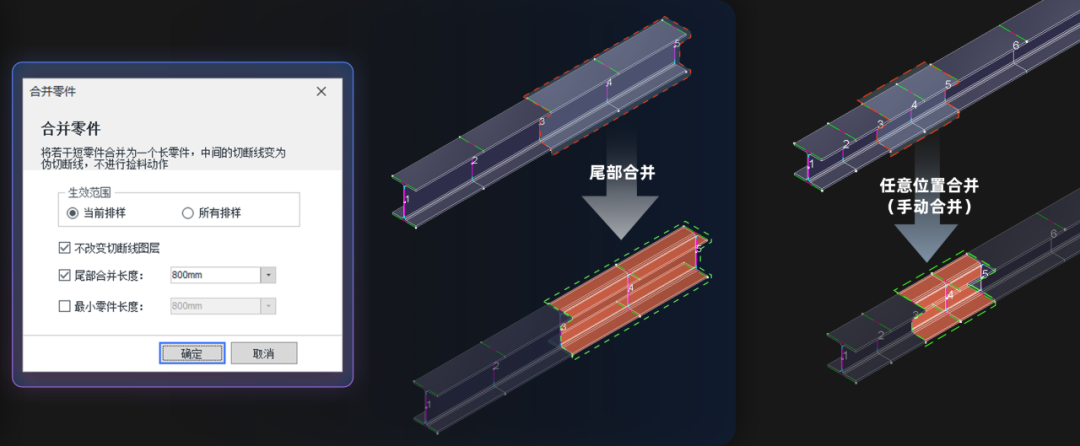

Uluhlu olusebenzayo lwamacandelo adityanisiweyo luphuculwe. Kwiimeko apho amacandelo athile ekupheleni kombhobho kufuneka adlule ubude obuthile ukuze kuqhutywe isenzo se-PLC esihambelanayo ngenxa yeemfuno zesakhiwo somatshini wokusika umbhobho, umsebenzi "wokudibanisa" ungasetyenziselwa ukudibanisa amacandelo amaninzi amafutshane kwelinye. icandelo elide lokuqhubekeka. Inguqulelo entsha yesoftware ayixhasi kuphela ukudityaniswa kwamacandelo ngokuzenzekelayo kodwa ikwavumela ukudityaniswa kwezandla kwamacandelo achaziweyo. Abasebenzisi banokuseta uluhlu olusebenzayo kwaye baguqule umaleko womgca wokusikwa.

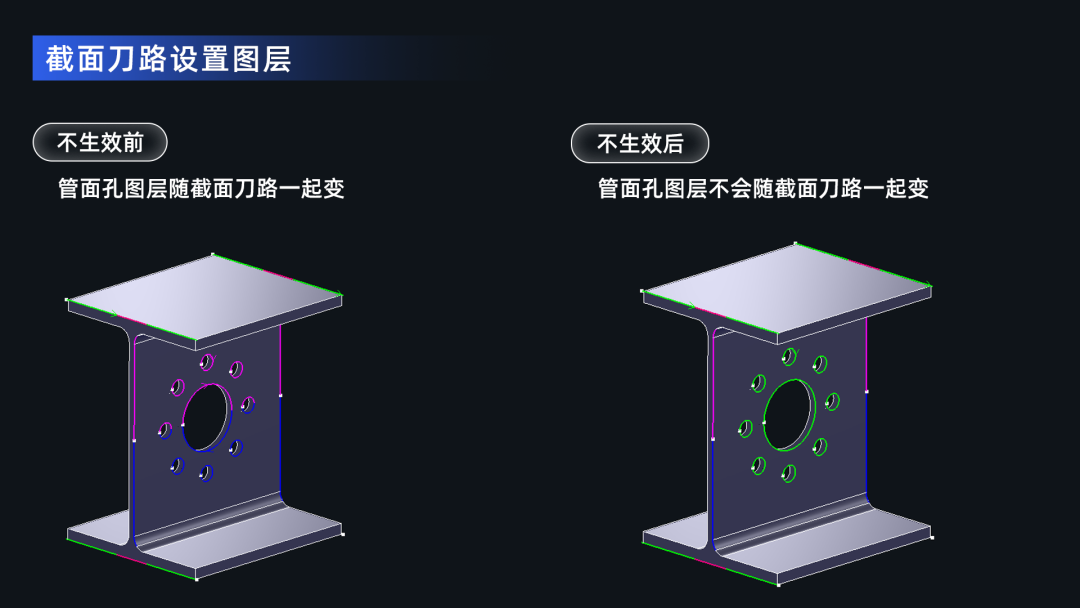

Indlela yokusika icandelo ngoku ingaqwalaselwa ukuba ingabandakanyi iileya ezithile ezisekelwe kwiimfuno zenkqubo. Inkqubo yazisa isalathisi esitsha sokucwangcisa iparameter yomaleko, evumela abasebenzisi ukuba babeke iileyile ezithile kumbhobho wombhobho ukuba ungabandakanyi xa uvelisa indlela yokusika icandelo.

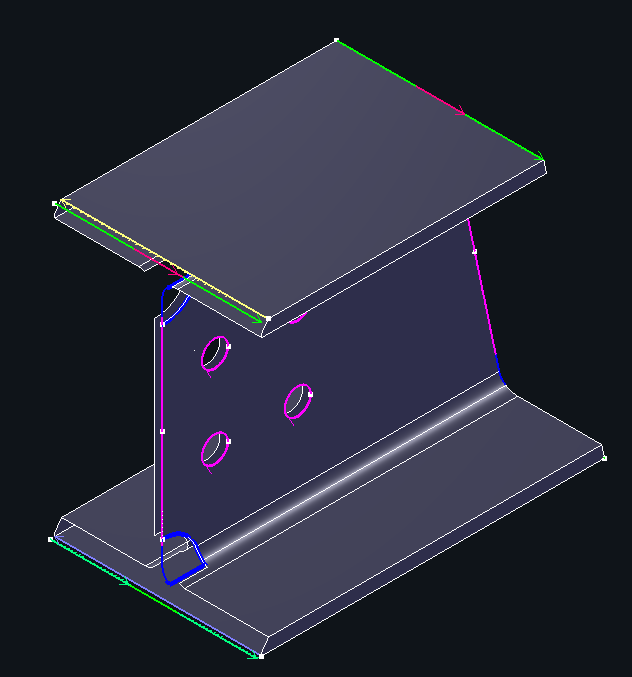

Umsebenzi we "H-beam end face cut optimization" uphuculwe. Inkqubo ngoku ixhasa ukuqondwa okuzenzekelayo kwe-H-beam ekupheleni kobuso beendlela zokusika i-bevel. Iyakwazi ukuguqula ngokuzenzekelayo i-bevel kunye ne-welding hole iimpawu kwi-H-beam ekupheleni kobuso kwiindlela ezithile zokusika, ukunciphisa ixesha elichithwe ekusebenzeni ngesandla kunye nokuphucula ukusebenza kakuhle kwemveliso.

Ujongano lokuhlela lwe-2D ngoku luxhasa ukongezwa kwemizobo egqumayo. Inqaku elitsha eligqumayo livumela abasebenzisi ukuba bangenise imizobo yefomathi yeDXF, ngenkxaso yemephu yomaleko, ukuqondwa okuzenzekelayo kokumakisha okubhaliweyo, ukujonga kwangaphambili kwe-3D, ukuhluma, kunye nokujikeleza. Imizobo esongelwe kumphezulu wombhobho ingasetyenziswa njengeendlela zokusika, ivumela ukusetyenzwa kweepateni ezahlukeneyo, uyilo, okanye amacandelo obugcisa kumphezulu wombhobho.

Umsebenzi "ozenzekelayo wokuguqula i-contour vectors" ulungiselelwe. Xa intloko yokusika isondela kwikona ye-R ye-H-beam, ukuba i-flange ikhubaza kodwa intloko yokusika ayiguquki kwangaphambili, umgama phakathi kwe-flange kunye nentloko yokusika iba yinto ebalulekileyo, echaphazela ukusetyenzwa. Inguqulelo entsha yesoftware yazisa "umgama we-swing", ukuvumela intloko yokusika ukuba ijike kwangaphambili xa isondela kwikona ye-R, ngokusekelwe kumgama osetyenzisiweyo wokuguqula, ukuphepha ukuguqulwa kwe-flange kunye nokuqinisekisa ukusika ngokufanelekileyo.

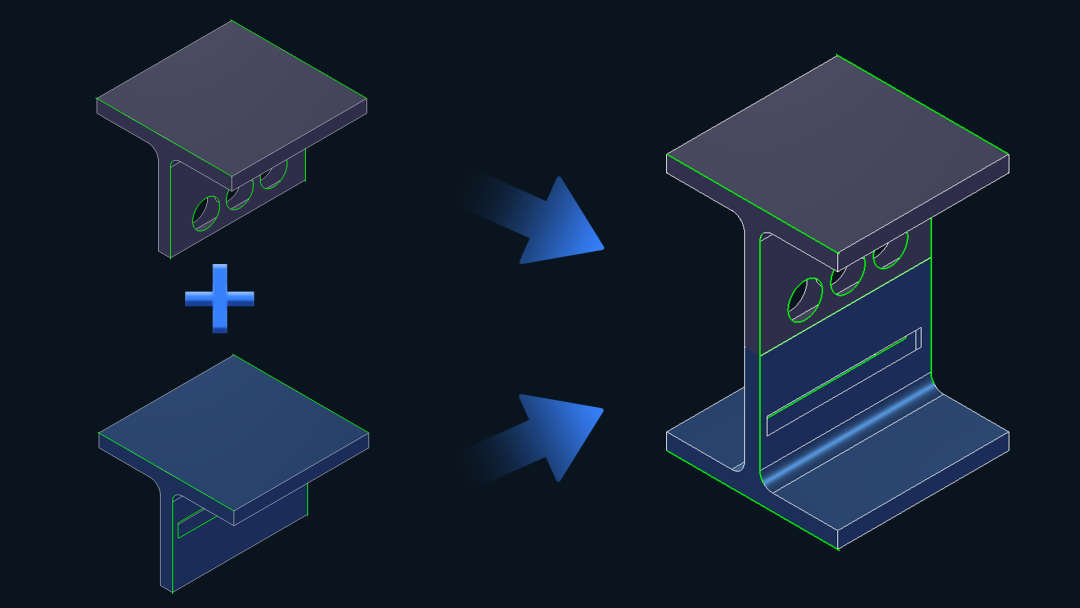

Inkqubo ngoku ixhasa ukudibanisa i-T-shaped steel components kwi-I-beams. Ekuqhutyweni kwangempela, ukuba imizobo yecandelo lensimbi ene-T ifunyenwe kodwa kukho imfuneko yokucubungula amacandelo amabini ensimbi ene-T kwi-H-beam, umsebenzi "wokudibanisa kwi-I-beam" ungasetyenziselwa ukuphucula ukusebenza kakuhle kokuhlela. iindlela zokusika kunye nokucwangciswa kwemveliso.

Isici se-nesting ngoku ibandakanya inketho yokudibanisa i-oblique cutting. Xa amacandelo e-T ahlanganiswe kwi-H-beam kwaye umgca wokusika ubekwe phakathi, inkqubo ivumela i-nesting ngokuzenzekelayo kunye ne-oblique okanye i-straight cut joints, ngaloo ndlela iphucula ukusetyenziswa kwe-nesting.

Inkqubo yazisa "isenzo somatshini wokubonisa izixhobo (bevel) ngexesha lokulinganisa". Xa yenziwe yasebenza, ukulinganisa kuya kubonisa iintshukumo zeechucks ezimbini ngexesha lokuqhuba. Ukuba ukusetyenzwa kwangempela kubandakanya amacandelo e-beveled, ukulinganisa kuya kubonisa izenzo zokusika i-bevel, ukuququzelela ukujonga.

Inkqubo ngoku ixhasa ukuguqulwa okuzenzekelayo kwee-engile ze-R kumacandelo efomathi ye-T2T. Ngomsebenzi omtsha othi "guqula i-T2T yecandelo elingu-R", amacandelo angeniswe ngaphandle angaguqulwa ngokuzenzekelayo ukuze atshatise i-engile engu-R efunwayo, kuthintelwa imfuno yokusebenza ngokutsha okanye ukuguqulwa xa i-engile yecandelo le-R ingahambelani ne-engile eyi-R yombhobho.