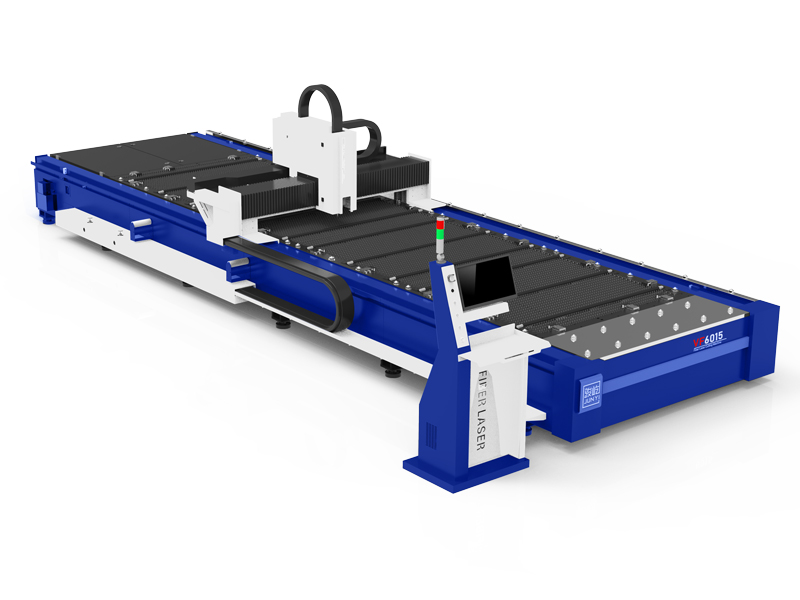

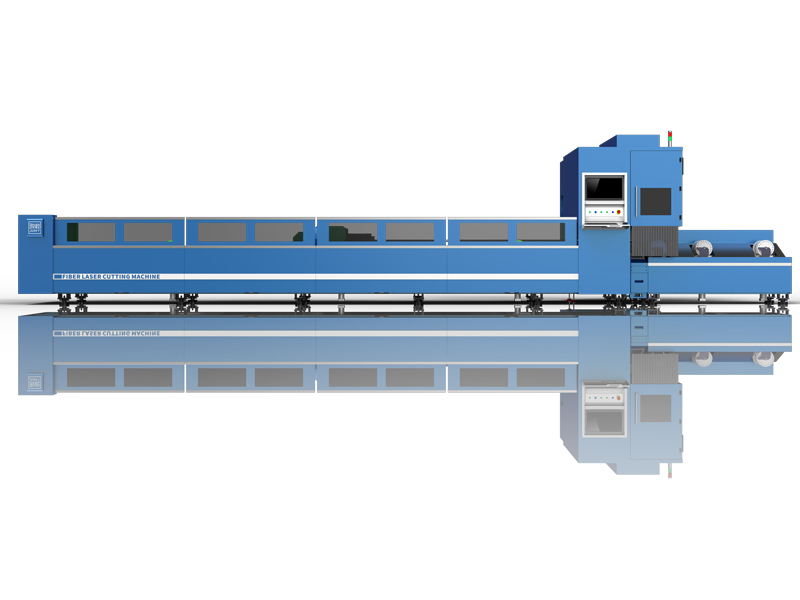

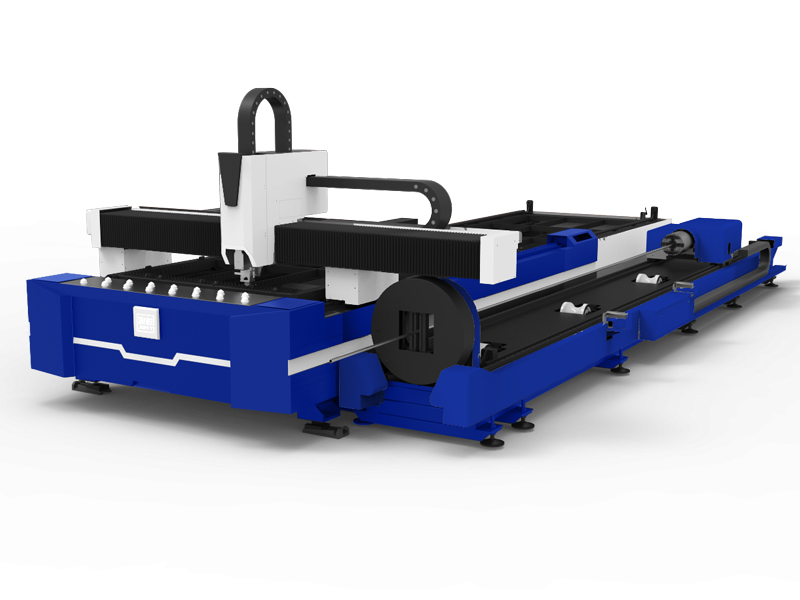

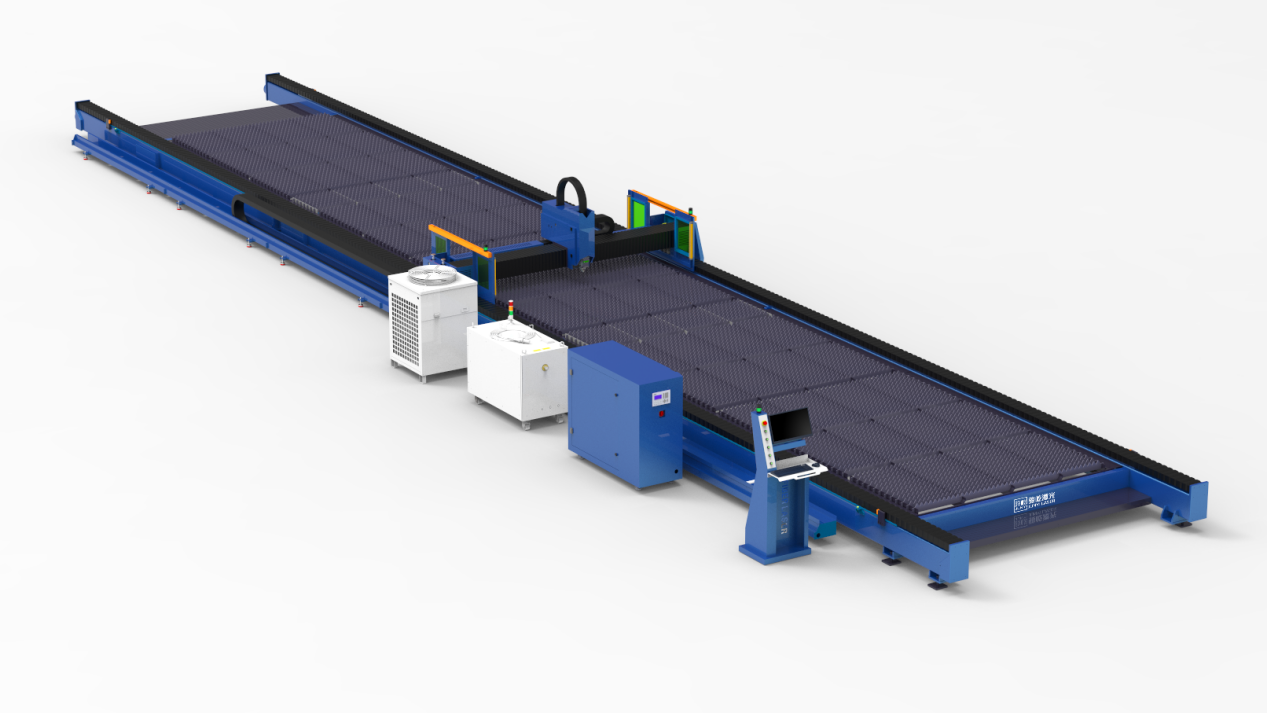

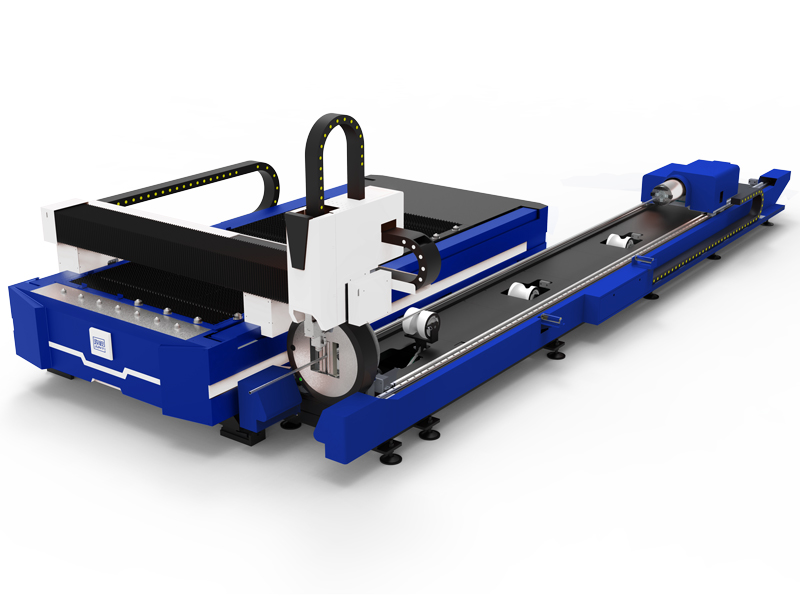

Semi-automatic feeding fiber laser pipe cutting machine

Video

SPECIFICATIONS

Performance index parameters |

Detailed parameters |

Laser power |

3000-6000W |

Loading method |

Automatic loading |

Chuck clamp tube diameter |

Φ10mm-Φ160mm/Φ10mm-Φ230mm |

Material Type |

Round tube, square tube, rectangular tube, oval tube, etc. |

X-axis travel: Maximum processing pipe size |

6500mm |

Y-axis travel |

600mm |

Z-axis travel |

250mm |

X/Y axis positioning accuracy |

±0.05mm/m |

X/Y axis repeat positioning accuracy |

±0.03mm |

X/Y axis single axis maximum positioning accuracy |

120m/min |

B axis maximum positioning speed |

160rpm |

B-axis positioning accuracy |

±30’’ |

B axis repeat positioning accuracy |

±10’’ |

Maximum load-bearing capacity of chuck |

200KG |

Phase number/power rating/voltage frequency |

3-phase/380V/50-60Hz |

Total power protection level |

IP54 |

X-axis travel: Maximum processing pipe size |

6500mm |

Machine dimensions |

About 10500*2600*2300mm |

Material |

thickness (mm) |

Gas Type |

1000W |

1500W |

2000W |

3000W |

4000W |

6000W |

|

Stainless steel

|

|

|

speed(m/min) |

speed(m/min) |

speed(m/min) |

speed(m/min) |

speed(m/min) |

speed(m/min) |

1 |

N2 |

18~20 |

25~30 |

25~35 |

25~40 |

30~54 |

30~60 |

|

2 |

N2 |

5~6 |

8~10 |

10~12 |

18~20 |

18-24 |

30-36 |

|

3 |

N2 |

2.8~3.5 |

4~4.5 |

4~6 |

8~10 |

10~15 |

15~20 |

|

4 |

N2 |

1.2~1.5 |

1.5~1.7 |

2.8~3.2 |

3~4 |

7~8 |

11~14 |

|

5 |

N2 |

|

0.8~1 |

1.6~2 |

3~4 |

5~5.5 |

7~8 |

|

6 |

N2 |

|

0.8 |

1~1.2 |

2.2~3 |

3.6~4 |

5~6 |

|

8 |

N2 |

|

|

0.5~0.6 |

1.2~1.5 |

1.5~2 |

3.8~4.2 |

|

10 |

N2 |

|

|

|

0.5-0.8 |

1.2~1.6 |

1.8~2.2 |

|

12 |

N2 |

|

|

|

|

0.8~0.85 |

1.2~1.5 |

|

14 |

N2 |

|

|

|

|

|

0.9~1 |

|

16 |

N2 |

|

|

|

|

|

0.65~0.75 |

|

|

Carbon Steel

|

1 |

O2 |

14~16 |

22~24 |

20~25 |

25~30 |

35~40 |

40~50 |

2 |

O2 |

6~8 |

8~10 |

13 |

13 |

20 |

25-30 |

|

3 |

O2 |

3.4~3.7 |

3.6~3.8 |

4~4.2 |

3.5~4.5 |

4.2~4.5 |

4~4.5 |

|

4 |

O2 |

2 |

2.5 |

3.5 |

3.5 |

3.8 |

3.8 |

|

5 |

O2 |

1.6 |

2 |

2.5~3 |

2.5~3 |

2.5~3 |

3.2~3.7 |

|

6 |

O2 |

1.4 |

1.4~1.5 |

2~2.5 |

2.2~2.8 |

2.4~2.8 |

2.8~3.4 |

|

8 |

O2 |

1~1.3 |

1.2~1.3 |

1.2~1.5 |

1.6~2 |

1.8~2.1 |

2.5~2.8 |

|

10 |

O2 |

0.8~0.9 |

1.0~1.1 |

1.1~1.2 |

1.1~1.4 |

1.2~1.4 |

1.4~2.2 |

|

12 |

O2 |

|

0.8~1 |

0.9~1 |

0.9~1.1 |

0.9~1 |

0.9~1.8 |

|

14 |

O2 |

|

0.6 |

0.8~0.9 |

0.8~0.9 |

1 |

0.8~1.3 |

|

16 |

O2 |

|

0.5-0.7 |

0.7~0.8 |

0.7~0.8 |

0.7~0.8 |

0.7~1 |

|

18 |

O2 |

|

|

|

0.65~0.7 |

0.65~0.7 |

0.65~0.75 |

|

20 |

O2 |

|

|

|

0.55~0.65 |

0.55~0.65 |

0.6~0.7 |

|

25 |

O2 |

|

|

|

|

|

0.4~0.5 |

|

|

aluminum

|

1 |

N2 |

15-20 |

18~20 |

18~24 |

25~40 |

25~40 |

30~50 |

2 |

N2 |

5~5.5 |

6~8 |

7~9 |

11 |

15~18 |

20~30 |

|

3 |

N2 |

1.2~1.4 |

2.5~3 |

3.3~4.2 |

8~10 |

8~10 |

12~16 |

|

4 |

N2 |

|

0.8~1 |

1.5~2.5 |

4 |

4.5~5.5 |

10~12 |

|

5 |

N2 |

|

|

1.2~1.5 |

1.5 |

2~3 |

6~10 |

|

6 |

N2 |

|

|

|

1.6~2 |

1.5~2 |

4~5.5 |

|

8 |

N2 |

|

|

|

|

|

1.2~2 |

|

10 |

N2 |

|

|

|

|

|

0.8~1 |

|

12 |

N2 |

|

|

|

|

|

0.5~0.7 |

|

14 |

N2 |

|

|

|

|

|

0.4~0.6 |

|

|

brass

|

1 |

N2 |

8~10 |

12 |

18~24 |

25~35 |

25~35 |

35~50 |

2 |

N2 |

2~2.5 |

5~6 |

5~7 |

12~15 |

12~15 |

20~30 |

|

3 |

N2 |

0.8~1 |

1.8~2 |

2~3 |

6~8 |

6~8 |

10~16 |

|

4 |

N2 |

|

|

|

3~4 |

3~4 |

6~8 |

|

5 |

N2 |

|

|

|

|

2~3 |

4.5~6.5 |

|

6 |

N2 |

|

|

|

|

|

3~4 |

|

8 |

N2 |

|

|

|

|

|

1.2~1.8 |

|

|

Copper

|

1 |

O2 |

|

6~8 |

10~12 |

15~20 |

18~20 |

25~35 |

2 |

O2 |

|

1.4~1.6 |

5~6 |

8~10 |

10~12 |

12~15 |

|

3 |

O2 |

|

|

|

|

|

2~3 |

|

4 |

O2 |

|

|

|

|

|

1~2 |

|

5 |

O2 |

|

|

|

|

|

1~2 |

|

6 |

O2 |

|

|

|

|

|

0.6~0.8 |

application area

Function Introduction

Equipment production process

after-sale service

2.During the equipment warranty period, if the equipment components have a fault due to quality reasons, our company will repair and replace the components free of charge, and provide free services. (Except for optical components, wearing parts, and damage caused by user operation errors)

3.Professional, meticulous and complete pre-sales, in-sales and after-sales service system provides guarantee for users' uninterrupted processing, including installation guide, maintenance guide, unloading guide, training guide, etc.

4.After the equipment is signed for, the warranty period for the whole machine (optical devices, lenses and other wearing parts and consumables are not covered by the warranty) is 1-2 years. Our company will help the purchaser coordinate issues regarding after-sales service for auxiliary equipment.

Sample diagram of pipe processing