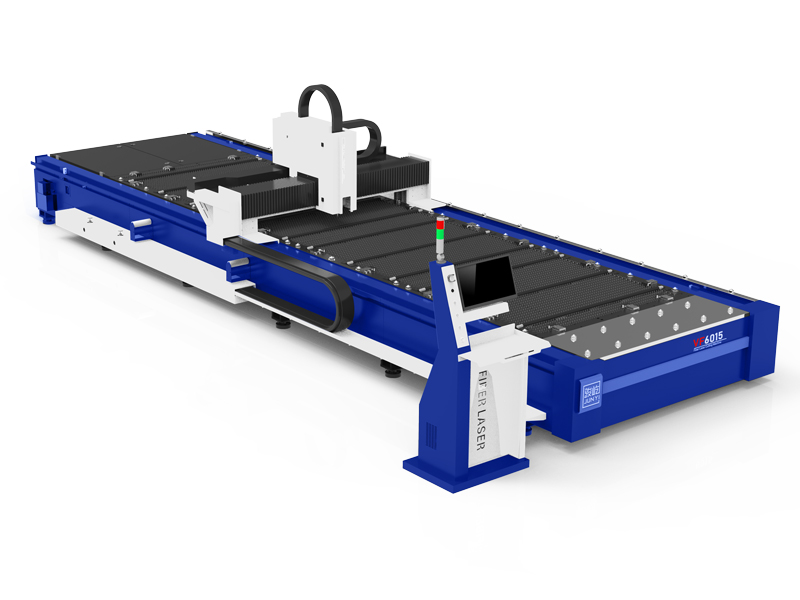

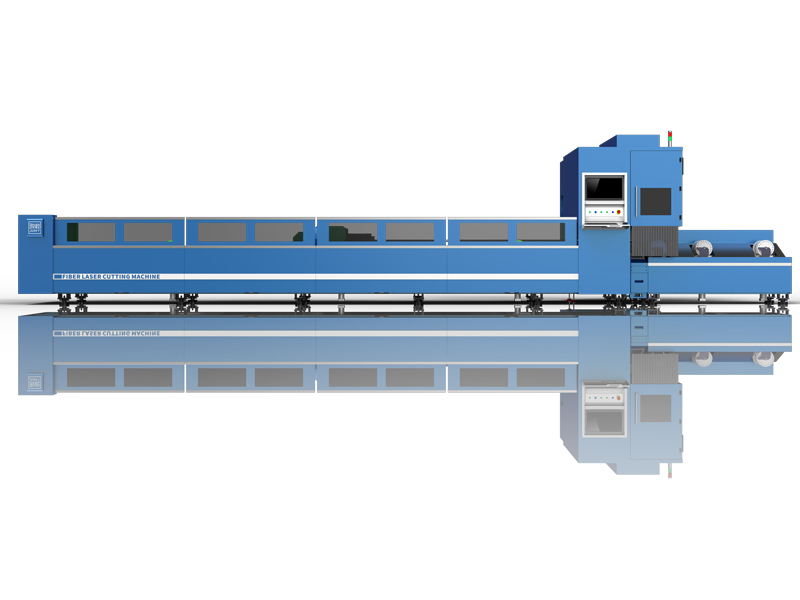

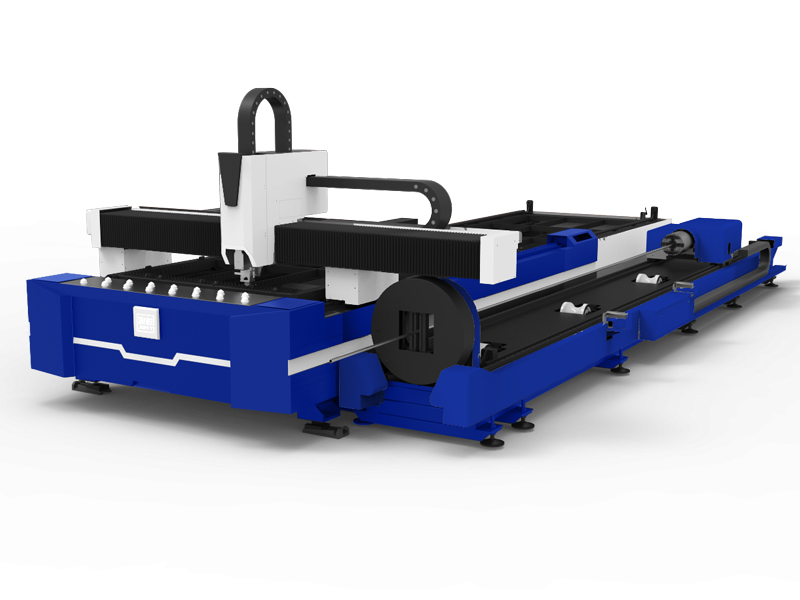

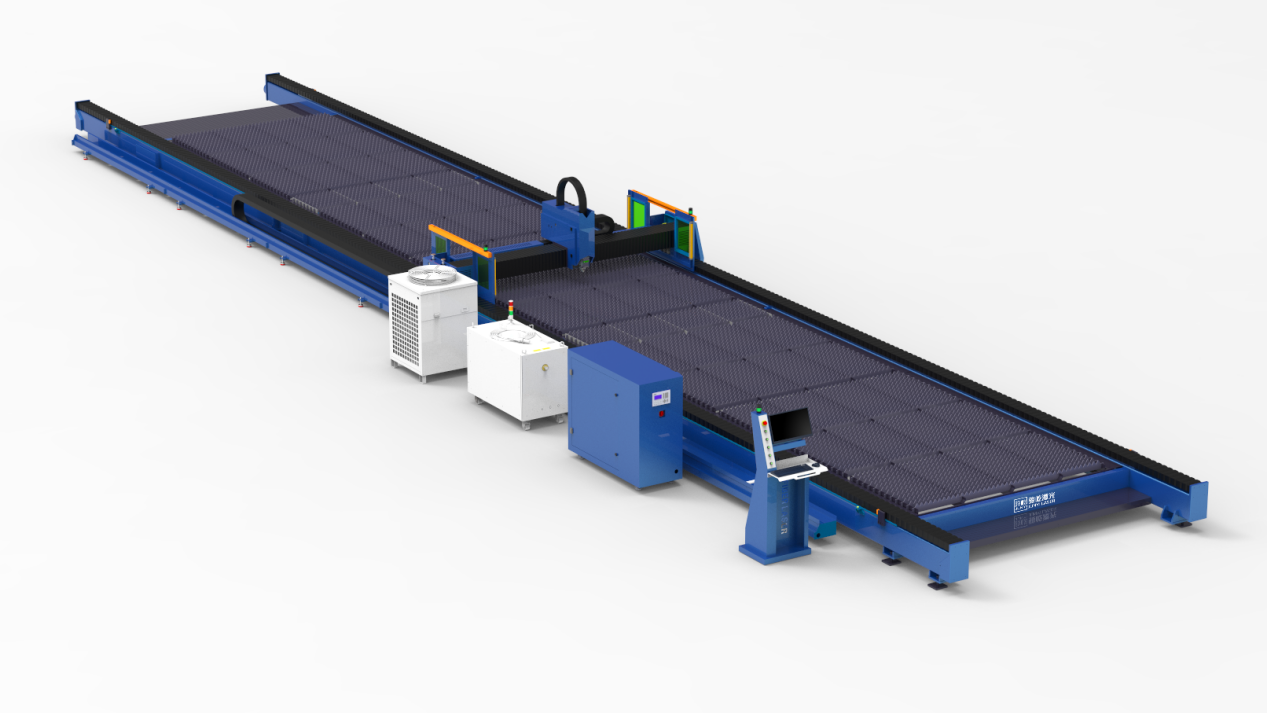

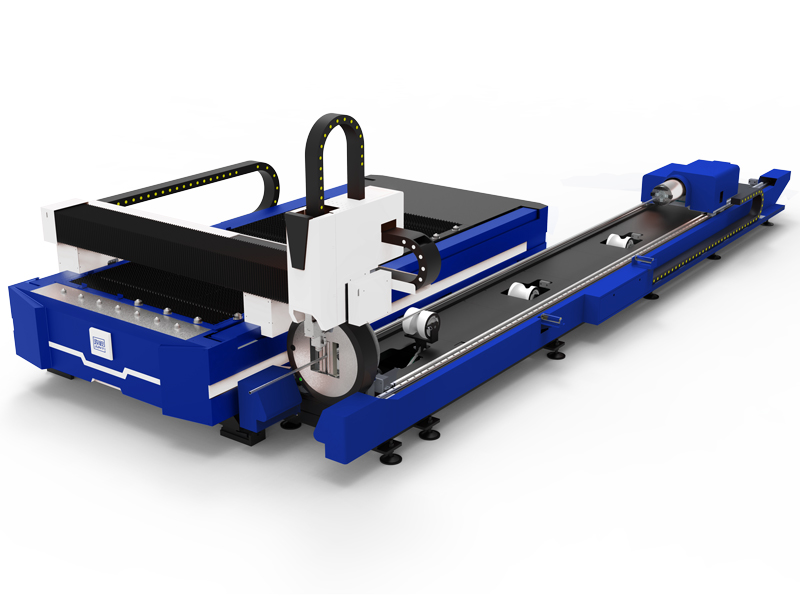

Laser cutting production line for section steel processing

Video

technical parameter

|

Technical parameter |

||

|

No. |

Item |

Parameter |

|

1 |

Cutting area |

Web 150mm≤H≤600mm Wing 100mm≤H≤500mm |

|

2 |

H-beam cutting length |

L≤12000mm |

|

3 |

Travel range |

X-axis travel: 13000mm (single table) / 24000mm (double table) Y-axis travel: 2500mm Z-axis travel: 910mm |

|

4 |

Positioning accuracy |

X/Y:±0.1mm |

|

5 |

Repeat positioning accuracy |

X/Y:±0.05m |

|

6 |

AC axis swing angle |

0.5G |

|

7 |

AC axis swing angle |

±90° |

|

8 |

Maximum processing wall thickness |

25mm (12KW) / 40mm (20KW) |

|

9 |

Maximum groove angle |

±38° |

|

10 |

Processable types |

L-beam / C-beam / H-beam / I-beam, etc. |

|

11 |

Daily processing volume |

About 30~50 tons |

Structure of machine

|

1. Mobile platform |

7. Cutting head |

|

2. Cantilever beam |

8. Laser measurement sensor |

|

3. Main console |

9. Protective cover |

|

4. Remote control handle |

10. Graphite protective plate |

|

5. Z axis |

11. Chiller |

|

6. AC axis |

12. Laser |

Operation process

competitive edge

Strategic partners

Application industry

Sample Display