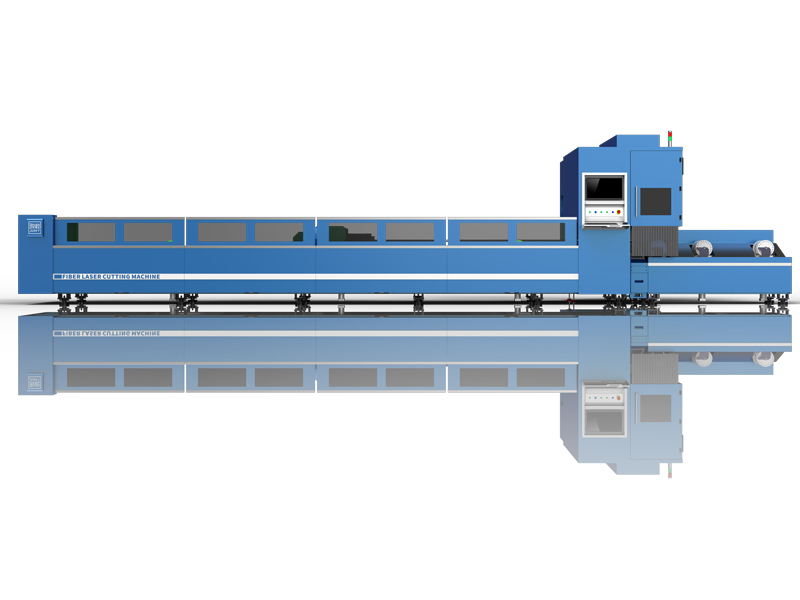

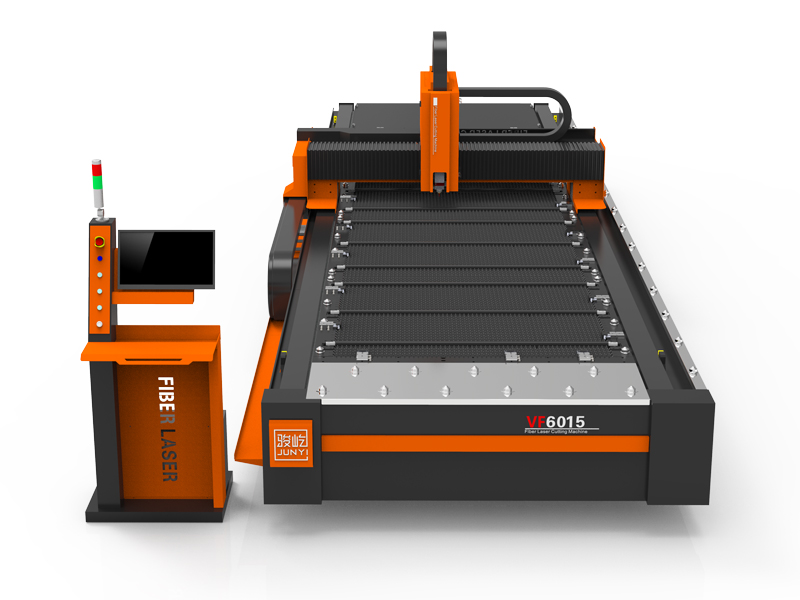

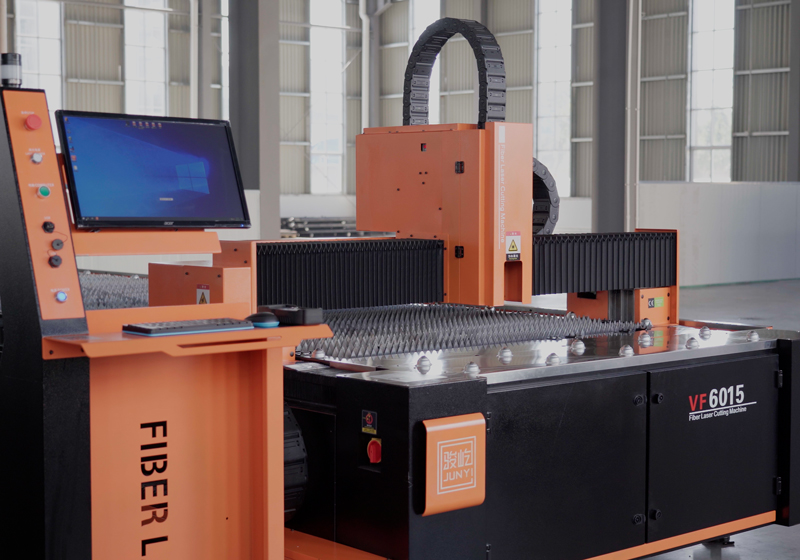

Kuthuthukiswe I-6 Meters Fiber Laser Cutter NgeSoftware Entsha Kakhulu

Ividiyo

IMICIMBI

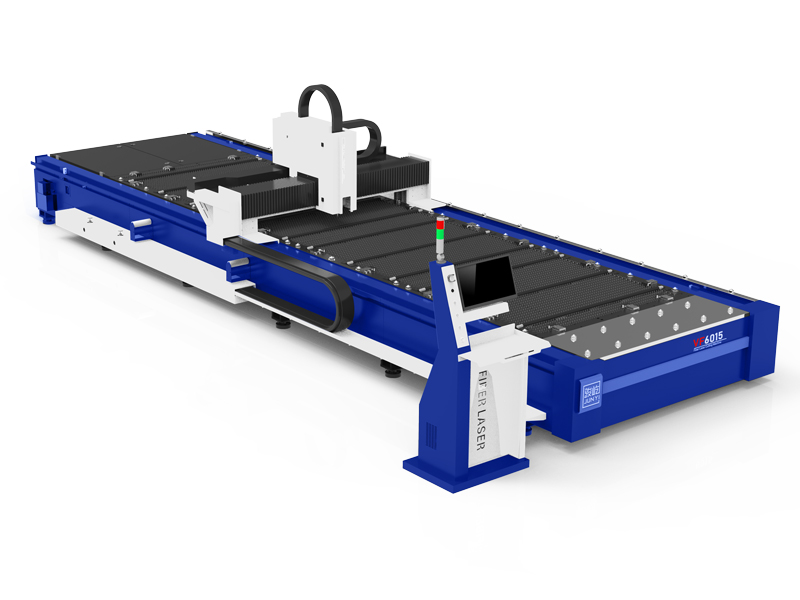

Ifomethi yokucubungula (L*W) | 6000*1500mm |

Amandla e-laser | 1500-6000W |

Ukunemba kokuma kwe-eksisi ye-X/Y | ±0.03mm/m |

X/Y ukunemba kokuphinda kokuma kwe-eksisi | ±0.03mm/m |

Ukusheshisa okuphezulu | 0.8G |

Isivinini esiphezulu | 80 m/min |

Ukunikezwa kwamandla kagesi | I-AC380V±5% 50/60Hz 3Phase |

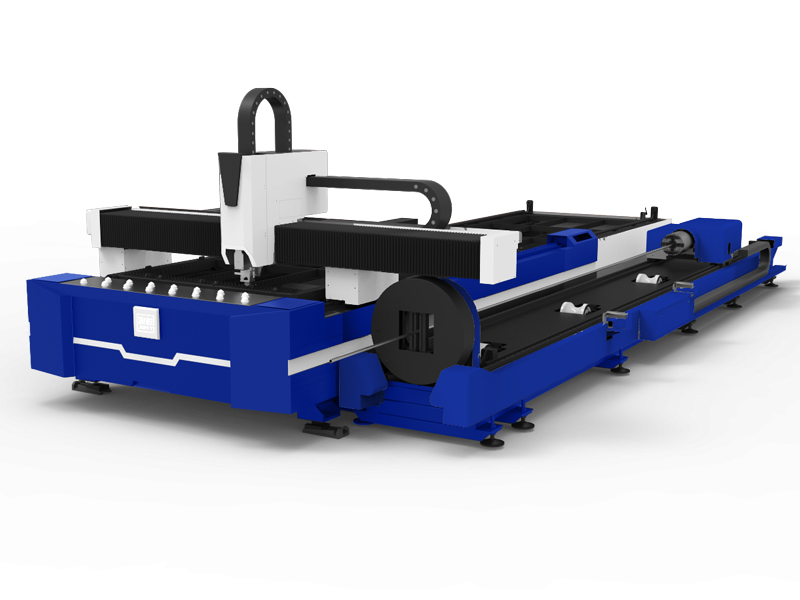

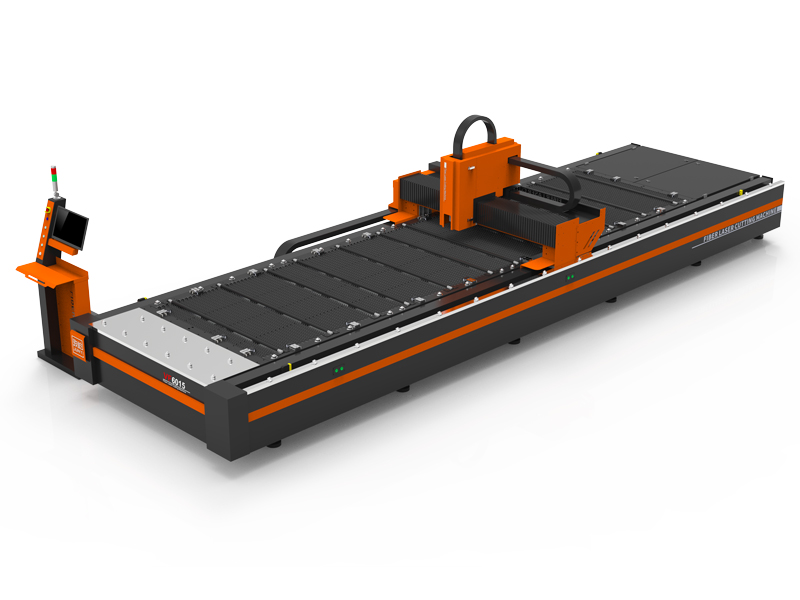

Ukusebenza kahle kuyinto ehamba phambili embonini yokukhiqiza, futhi lo mshini wokusika i-laser uletha ukusebenza okuyingqayizivele. Ijubane layo lokusika elihlaba umxhwele livumela ukuqedwa okusheshayo kwenani elikhulu lamapaneli eminyango, kuthuthukisa kakhulu ukusebenza kahle kokukhiqiza. Ngalo mshini, abakhiqizi bangahlangabezana nezikhathi ezimisiwe ngaphandle kokuyekethisa ikhwalithi.

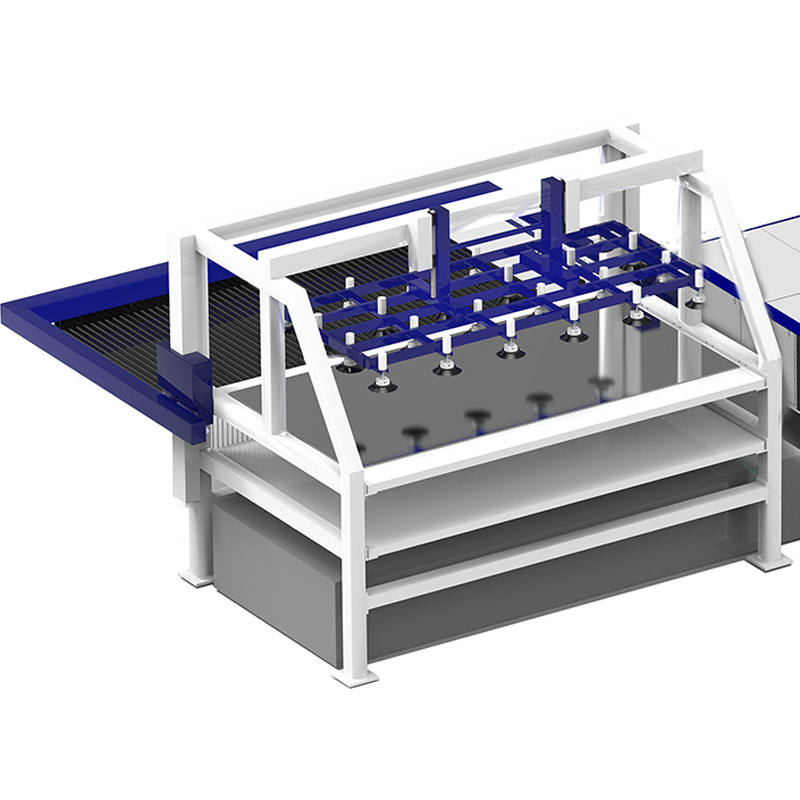

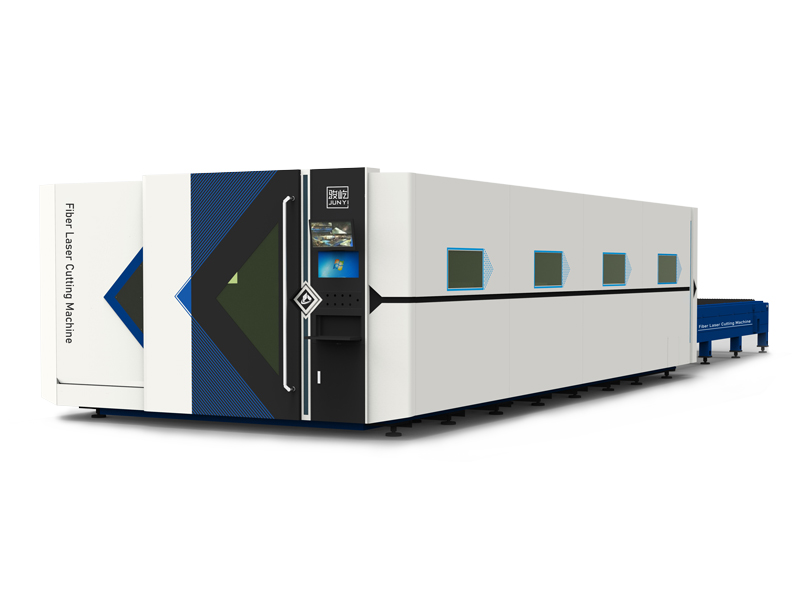

I-Automation ingesinye isici esiphawulekayo salo mshini wokusika we-laser. Uma ibhangqwe nesistimu yokulawula ikhompyutha, ingafinyelela inqubo yokusika ezenzakalelayo ngokugcwele. Lokhu kunciphisa isidingo sokusebenza mathupha, ukukhiqiza lula, futhi kuqinisekisa izinga eliphezulu njalo.

IZINZUZO ZOMKHIQIZO

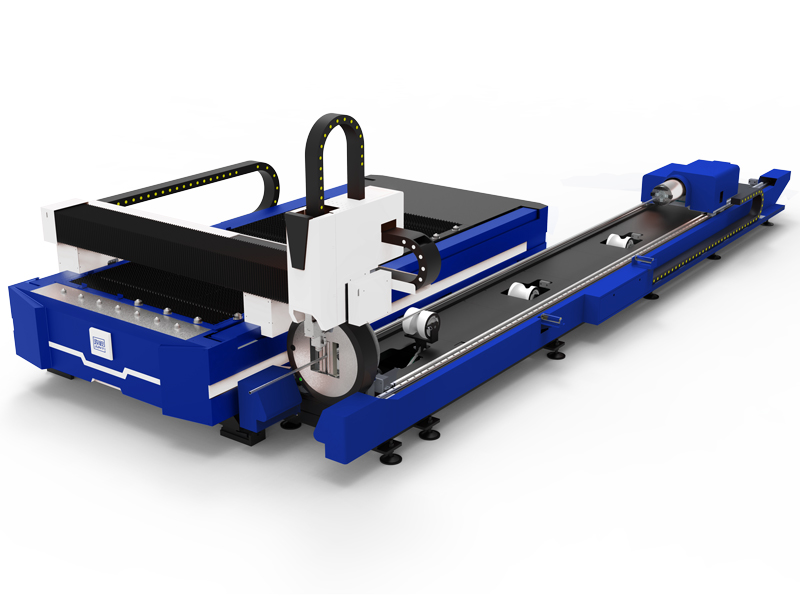

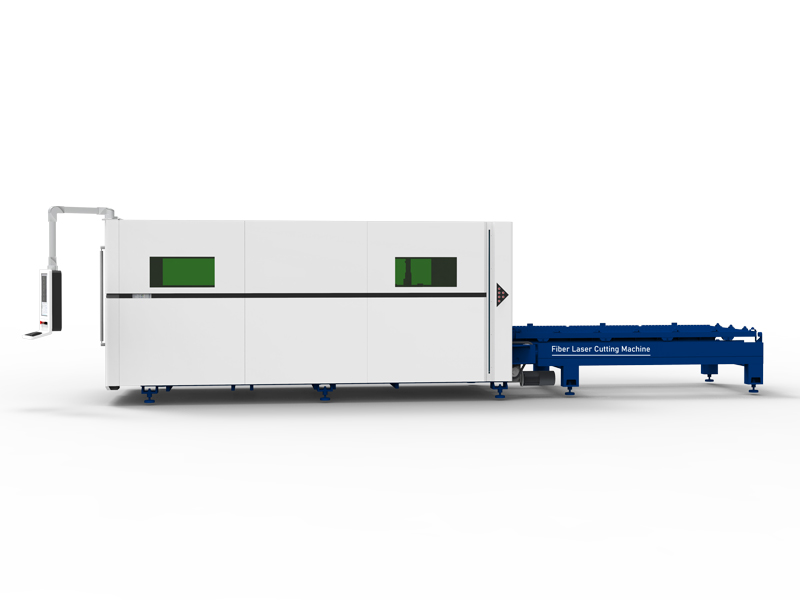

Ibanga elikhudlwana lokusika

Ukusebenza kahle kokukhiqiza okuphezulu

Izinkambu zohlelo lokusebenza ezibanzi

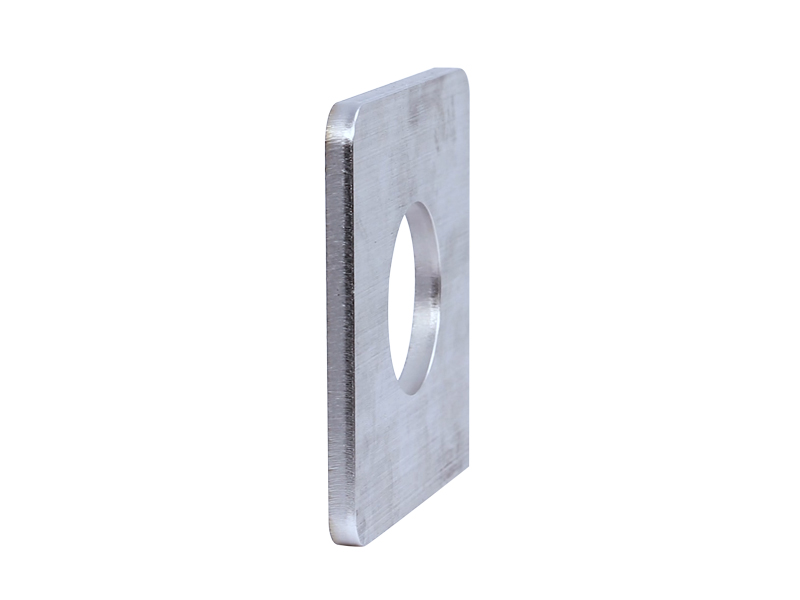

Ukunemba okuphezulu kanye nekhwalithi

Izinketho