I-Shanghai Bochu Electronics Company Iqala Uhlelo Lwakamuva: TubesT_V1.51 ekupheleni kukaJanuwari 2024

I-Shanghai Bochu Electronics Company imemezele ukukhishwa kwesistimu yayo yakamuva, i-TubesT_V1.51, ekupheleni kukaJanuwari 2024. Lolu hlelo luhlinzeka ngendlela elula yokudweba ehambisana nepharamitha yezimboni zezitebhisi, zomzila wesitimela, nezinqola zezandla. Isekela ukukhiqizwa okusheshayo kwezingxenye ezifana namabha avundlile, amakholomu, amabha aqondile, namapayipi angaphezulu anezingxenye zeshubhu eziyindilinga noma eziyisikwele. Iphinde inikeze izindlela ezihlukene zokuhlanganisa, okuhlanganisa "ukumaka ukushisela" noma "ukuhlanganiswa kokufakwa."

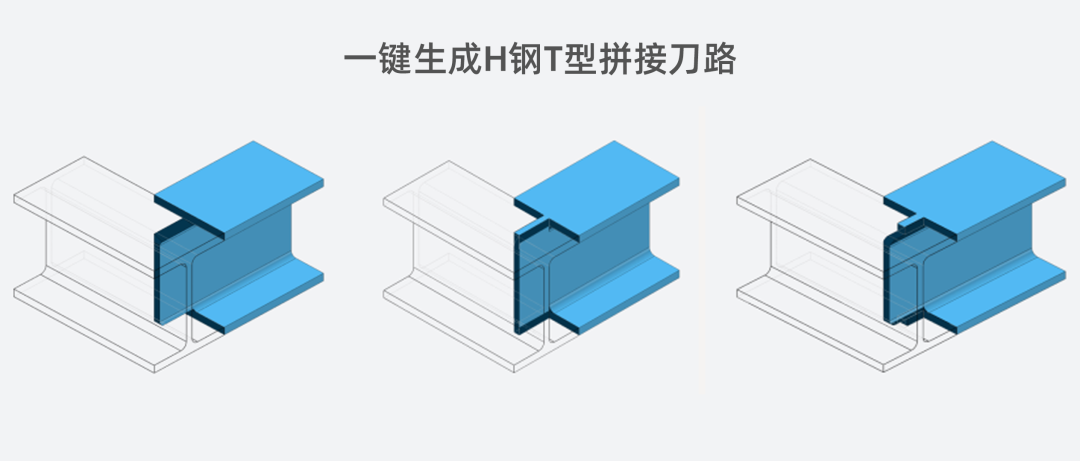

Uhlelo olusha futhi lusekela ukukhiqizwa okuzenzakalelayo kwezindlela ezihlukahlukene zokusika ze-H-beam/I-beam T-joint. Ezingxenyeni ze-H-beam (noma i-I-beam) ezidinga ukuxhumana kwe-T-joint, isistimu yethula umsebenzi wokuchofoza okukodwa ukuze ikhiqize indlela yokusika yejoyinti le-T. Lokhu akugcini nje konga isikhathi ekudwebeni nasekucutshungulweni kwezandla kodwa futhi kuthuthukisa ukusebenza kahle kokukhiqizwa nokucubungula kwangempela.

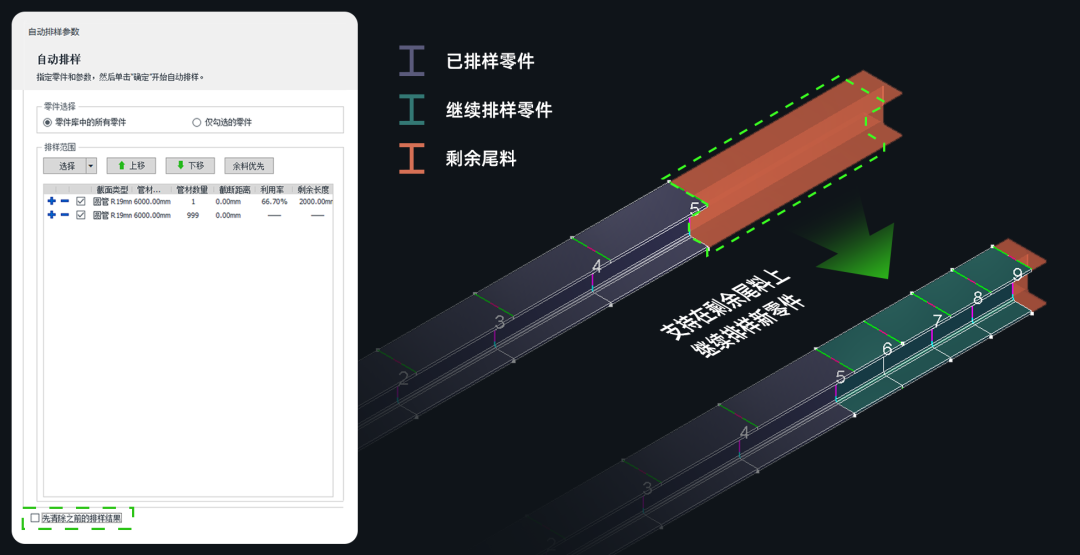

Ukuzalela okuqhubekayo manje sekuyatholakala esicini sokuzalela esizenzakalelayo. Uma inketho "ecacile yemiphumela yokuzalela yangaphambilini" ingakhethiwe, abasebenzisi bangaqhubeka nokuzalela ngokusekelwe emiphumeleni ekhona, ngaleyo ndlela bathuthukise ukusetshenziswa kwezinto zamapayipi.

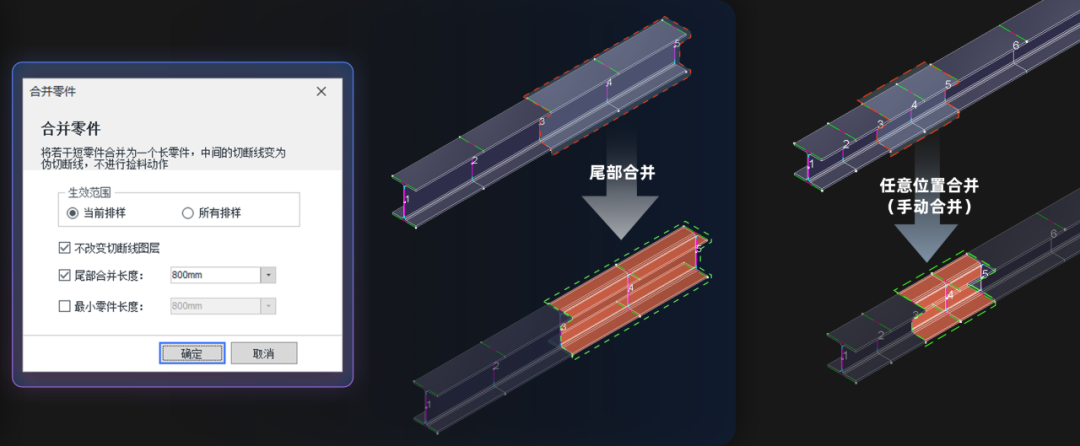

Ububanzi obusebenzayo bezingxenye ezihlanganisiwe buthuthukisiwe. Ezimeni lapho izingxenye ezithile ekugcineni kwepayipi kufanele zidlule ubude obuthile ukuze zenze isenzo se-PLC esihambisanayo ngenxa yezidingo zesakhiwo somshini womshini wokusika amapayipi, umsebenzi “wokuhlanganisa” ungasetshenziswa ukuhlanganisa izingxenye eziningi ezimfushane zibe yinto eyodwa. ingxenye ende yokucubungula. Inguqulo entsha yesofthiwe ayisekeli kuphela ukuhlanganiswa okuzenzakalelayo kwezingxenye kodwa futhi ivumela ukuhlanganiswa ngesandla kwezingxenye ezishiwo. Abasebenzisi bangaphinda basethe ububanzi obusebenzayo futhi balungise isendlalelo somugqa osikiwe.

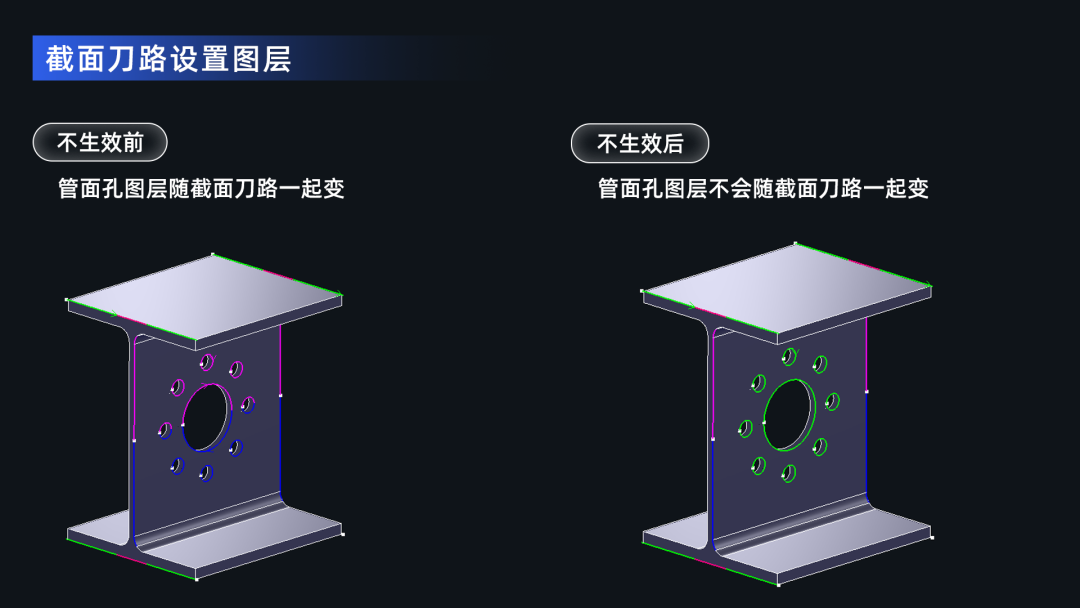

Indlela yokusika ingxenye manje ingalungiselelwa ukuze ingafaki izendlalelo ezithile ngokusekelwe ezidingweni zenqubo. Isistimu yethula isici esisha sokumisa ipharamitha yesendlalelo, evumela abasebenzisi ukuthi basethe izendlalelo ezithile endaweni yepayipi ukuze zingabandakanywa lapho kukhiqizwa indlela yokusika isigaba.

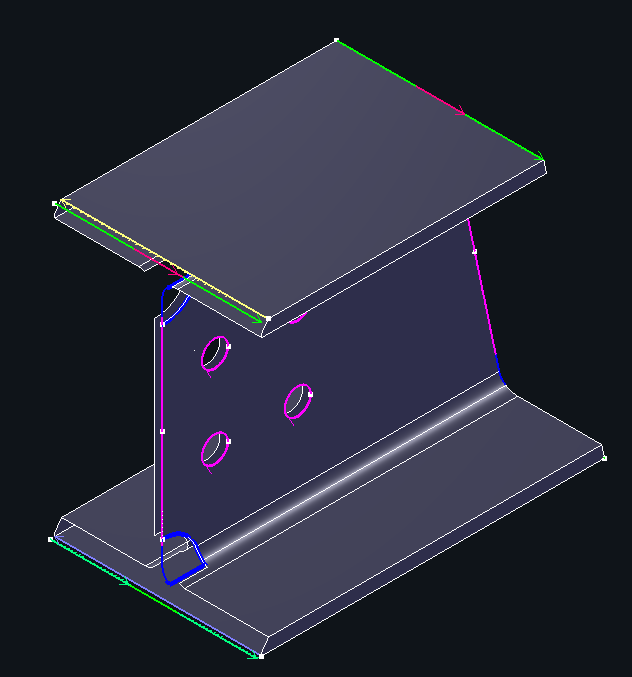

Umsebenzi othi "H-beam end cut face cutting optimization" umsebenzi uthuthukisiwe. Isistimu manje isekela ukuqashelwa okuzenzakalelayo kwemizila yokusika yobuso be-bevel ye-H-beam. Ingakwazi ukuguqula ngokuzenzakalelayo izici ze-bevel kanye nembobo yokushisela ebusweni bokuphela kwe-H-beam ezindleleni ezithile zokusika, inciphise isikhathi esichithwa ekucutshungulweni kwezandla kanye nokwenza ngcono ukusebenza kahle kokukhiqiza.

Isixhumi esibonakalayo sokuhlela se-2D manje seseka ukwengezwa kwezithombe ezisibekelayo. Isici esisha semvilophi sivumela abasebenzisi ukuthi bangenise imidwebo yefomethi ye-DXF, ngokusekelwa kwemephu yesendlalelo, ukubonwa okuzenzakalelayo kombhalo wokumaka, ukubuka kuqala kwe-3D, ukuthwebula, nokuzungezisa. Imidwebo esongelwe endaweni yepayipi ingasetshenziswa njengezindlela zokusika, ezivumela ukucutshungulwa kwamaphethini ahlukahlukene, imiklamo, noma izingxenye zobuciko endaweni yepayipi.

Umsebenzi "wokuguqulwa okuzenzakalelayo kwama-contour vectors" uthuthukisiwe. Lapho inhloko yokusika isondela ekhoneni lika-R le-H-beam, uma i-flange ikhubazekile kodwa ikhanda lokusika lingaguquki kusengaphambili, ibanga phakathi kwe-flange nekhanda lokusika liba bucayi, lithinte ukucubungula. Inguqulo entsha yesofthiwe yethula ukulungiselelwa "kwebanga lokujika", okuvumela inhloko yokusika ukuthi inyakaze kusengaphambili lapho isondela ekhoneni le-R, ngokusekelwe ebangeni elimisiwe lokushwibeka, ukugwema ukuguqulwa kwe-flange nokuqinisekisa ukusika okufanele.

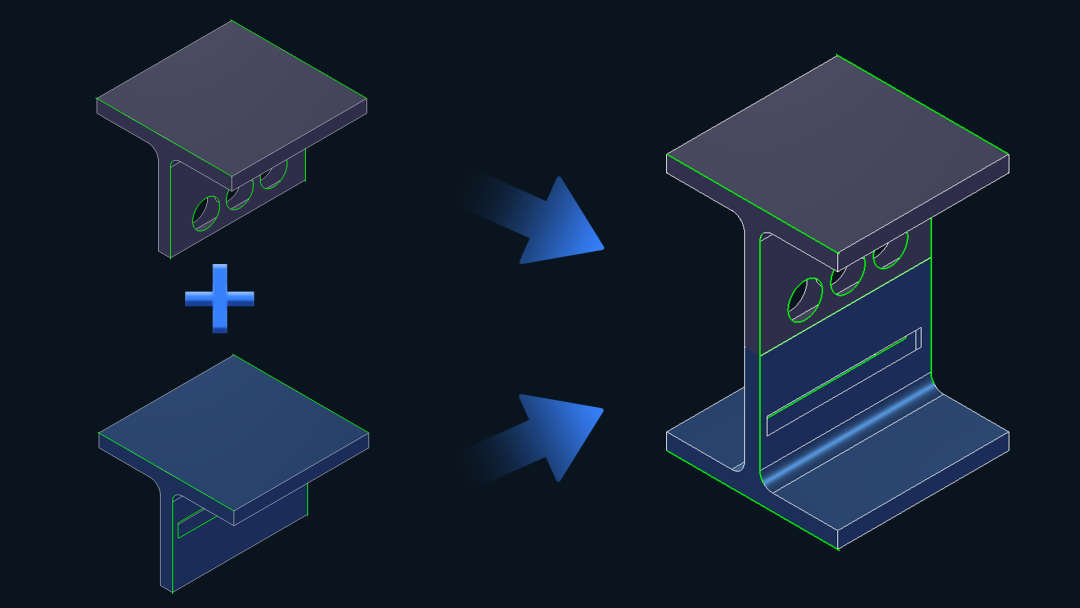

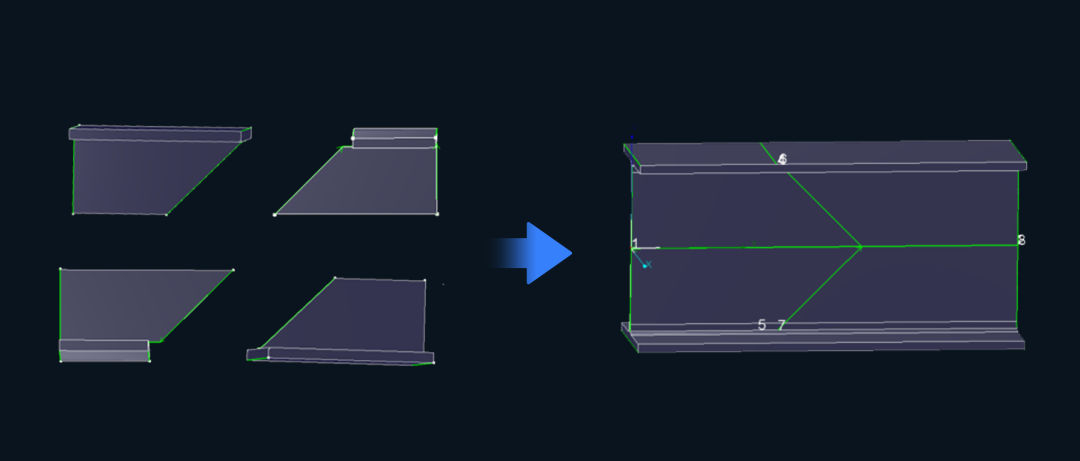

Isistimu manje isekela ukuhlanganisa izingxenye zensimbi ezimise okwe-T zibe imishayo ye-I. Ekucutshungulweni kwangempela, uma imidwebo yengxenye yensimbi emise okwe-T itholwa kodwa kunesidingo sokucubungula izingxenye ezimbili zensimbi ezimise okwe-T ku-H-beam, umsebenzi "wokuhlanganisa ube yi-I-beam" ungasetshenziswa ukuthuthukisa ukusebenza kahle kokuhlela. ukusika izindlela nokuhlela ukukhiqiza.

Isici sokuzalela manje sihlanganisa inketho yamalunga okusika i-oblique. Uma izingxenye ezimise okwe-T zihlanganiswa zibe i-H-beam futhi umugqa wokusika ubekwe phakathi, uhlelo luvumela ukuzalela okuzenzakalelayo okunama-oblique noma amalunga okusika aqondile, ngaleyo ndlela kuthuthukiswe ukusetshenziswa kwesidleke.

Isistimu yethula "izenzo zokubonisa ithuluzi lomshini (bevel) ngesikhathi sokulingisa". Uma kunikwe amandla, ukulingisa kuzobonisa izenzo zama-chuck amabili phakathi nokucubungula. Uma ukucutshungulwa kwangempela kuhlanganisa izingxenye ezine-beveled, ukulingisa kuzophinde kubonise izenzo zokusika i-bevel, okusiza ukubhekwa.

Isistimu manje isekela ukuguqulwa okuzenzakalelayo kwama-engeli angu-R wezingxenye zefomethi ye-T2T. Ngomsebenzi omusha othi “guqula i-T2T ingxenye engu-R ye-engeli”, izingxenye ezingenisiwe zingashintshwa ngokuzenzakalelayo ukuze zifane ne-engeli engu-R oyifunayo, kugwenywe isidingo sokusebenza kabusha noma ukuguqulwa lapho i-engeli yengxenye engu-R ingafani ne-engeli engu-R yangempela yepayipi.