Ukujongana neengxaki zeLaser Welding Gun: Ukukhanya okubuthathaka kunye nokuKhanya kwiNozzle yeCopper

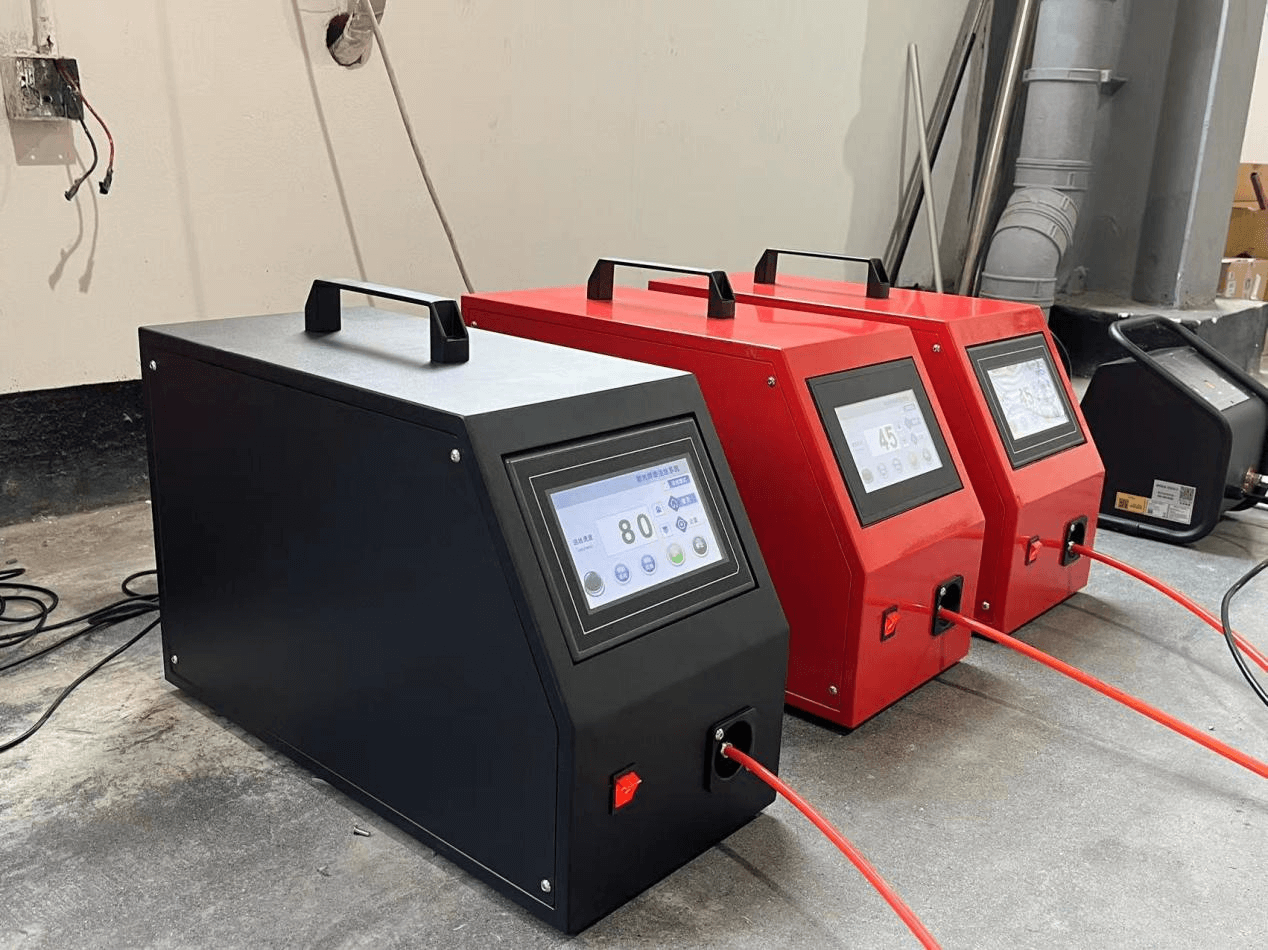

Umatshini wokuwelda weLaser zisetyenziswa ngokubanzi kumashishini ahlukeneyo ngokuchaneka kunye nokusebenza kakuhle. Nangona kunjalo, imiba enjengokukhanya obuthathaka kunye nokugqabhuka kwi-nozzle yobhedu inokuthintela inkqubo ye-welding. Kweli nqaku, siza kuhlalutya izinto ezinokubangela ezi ngxaki kwaye sinikeze izisombululo zokuthintela ukuba zingenzeki kwixesha elizayo.

Uhlalutyo lweMiba:

Ukukhanya okubuthathaka kunye nokungakwazi ukuxubha kunokubangelwa ngamacandelo e-lens eyonakeleyo, kubandakanywa iilensi zokukhusela, iilensi ezigxininisekileyo, iilensi ezidibanisayo kunye nezibonisi. Nawuphi na umonakalo kula macandelo unokukhokelela kwimiba ephawulweyo. Kunconywa ukuba uqale ngokutshintsha i-lens yokukhusela kwaye uhlolisise i-lens egxininisekileyo, i-reflector, kunye ne-collimating lens nayiphi na umonakalo. Ukutshintsha amacandelo e-lens eyonakeleyo kufuneka kuyisombulule ingxaki. Ukongeza, ukugqabhuka kumlomo wobhedu kusenokuba ngumba ogxininisekileyo, ekufuneka uqwalaselwe ngokunjalo. Kwakhona kubalulekile ukuhlola intloko ye-laser fiber optic nayiphi na inkunkuma okanye umonakalo.

Uhlalutyo lomonakalo weLens:

Ukuhlelwa komonakalo: I-motor swing engaqhelekanga ebangelwa ukuphazamiseka okanye ukungahambi kakuhle kwesibane esibomvu kunokutshisa iringi yokutywina kunye ne-lens.

I-Convex Surface Umonakalo wePlatform Lens: Olu hlobo lomonakalo ludla ngokubangelwa ukungcola ngexesha lokutshintshwa kwelensi ngaphandle kokukhuselwa okufanelekileyo. Ibonakala njengamabala amnyama.

Ukonakaliswa koMphezulu wePlatform wePlatform Lens: Ukubonakaliswa kwe-diffuse ye-laser beam kaninzi kubangela olu hlobo lomonakalo, olukhokelela kwiindawo ezigxilwe kwilensi kunye nokutshiswa kwengubo. Ibonakala njengamabala amhlophe. Kusebenza umgaqo ofanayo kwimiphezulu yeconvex.

Ukonakala kweLensi eKhuselekayo: Oku kudla ngokubangelwa yintsalela okanye ungcoliseko ngexesha lokutshintshwa.

Ukukhutshwa kokukhanya okungaqhelekanga ngenxa yomqadi weGaussian obukhali ngokugqithisileyo osuka kwilaser, okukhokelela kwindawo emhlophe ngequbuliso embindini wayo nayiphi na ilensi.

Ukulungisa ingxaki:

Ukusombulula imiba, kucetyiswa ukuba utshintshe amacandelo e-lens eyonakalisiweyo. Ngeenkqubo ezithile zokutshintsha, nceda ujonge kwincwadana yokufakela.

Amanyathelo othintelo:

Ukuze usebenze ngconofiber laser welding machinekwaye uphephe ukutshintshwa rhoqo okunxulumene nelensi ngexesha lokuwelda ngesandla, la manyathelo alandelayo okuthintela anokuthathwa:

Sebenzisa iilensi zomvelisi zoqobo, njengoko iilensi ezithengwe kwi-intanethi zisenokungaqinisekisi ukuhanjiswa kokukhanya.

Nika ingqalelo ekuthinteleni ungcoliseko ngexesha lokutshintshwa kwelensi.

Ziphephe iindlela zokuwelda ezithe nkqo, ngakumbi xa udibanisa izinto ezibonisa ukukhanya okuphezulu.

Khusela i-lens kumonakalo ngokuphumeza amanyathelo okukhusela.

Faka iilensi zokhuseleko ezonakeleyo ngokukhawuleza.

Ukuthintela ukuphazamiseka kunye nokuqinisekisa ukusekwa okusebenzayo.

Isiphelo:

Ngokuqonda izizathu zokukhanya obuthathaka kunye nokugqabhuka kwi-nozzle yethusi kwi-laser welding guns, ukuxazulula iingxaki ezifanelekileyo kunye namanyathelo okuthintela anokuphunyezwa. Oku kuya kunceda ukuqinisekisa ukusebenza kakuhle kunye nokusebenza kakuhle kwe-welding, ukunciphisa ixesha lokunciphisa kunye nokuphucula imveliso yonke.