What items need to be prepared before installing the laser cutting equipment?

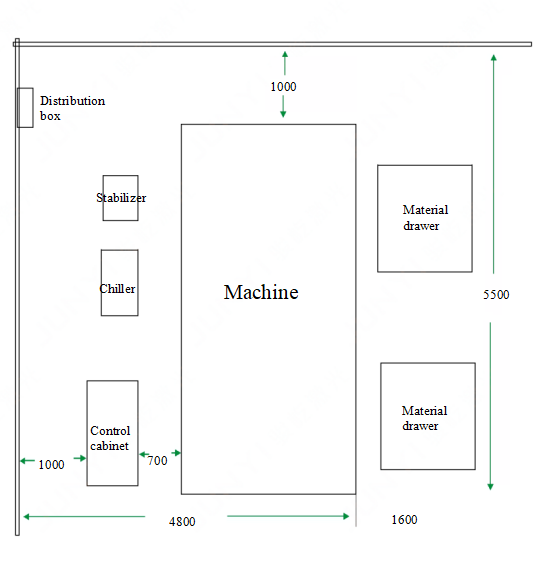

1.The left side of the cabinet and the back of the machine are more than 1.2m from the wall. If the air compressor is included in the whole production line, it could be placed out of the door. While if you place it in the factory, it should be away from the laser generator no more than 10m.

2. Prepare work

2.1 Power supply

(1) Specifications: three-phase five-wire system, 380V 50Hz, capacity depends on the type and capacity of the laser.

(2) Quality: Line voltage fluctuation <5%, single-phase 220V±5%, a three-phase regulated power supply is required to ensure stable input voltage of the equipment.

2.2 Grounding protection

It is recommended to ground the machine tool. The specific method is to connect the grounding wire to the grounding pin on the side of the machine tool. (The grounding resistance is less than 4 ohms)

2.3Factory environment

|

Items |

Description |

Remark |

|

Environmental temperature requirement |

15-28℃ |

|

|

Equipment storage temperature |

>5℃ |

|

|

Relative humidity requirement |

<60% |

|

|

Ground requirement |

Paint or terrazzo on the cement floor |

|

|

Indoor requirement |

Clean and dust-free environment |

A site environment with good ventilation, no dust, no corrosion, and no water leakage is required. |

Notice: Given that the control unit, servo unit and display are the core of the machine tool, and the machine tool should be protected from electromagnetic wave interference, such as argon arc welding or electrical discharge machining equipment, so as not to affect the normal operation of the machine tool and laser.

2.4 Basement of installation

The flatness of the ground is ±10mm, which can bear heavy objects of more than 6 tons, and there should be no large vibration around the installation foundation.

2.5Crane

Need to prepare a hydraulic forklift or aerial crane (specifications are based on the weight of the equipment, such as a 3.5-ton equipment requires a 5-ton forklift, or two 10-meter-long 10-ton slings)

2.6 Cooling water

The cooling circulating water of the water cooler requires the use of distilled water or deionized water, and the use of mineral water is prohibited. (The specification of the water tank of the chiller equipped with the cutting machine is 120L)

2.7 Standard of auxiliary gas

(1) Oxygen: When using liquid oxygen, a vaporizer (flow rate: 1.0 cubic meter/minute, pressure value: 2.0MPA) needs to be added to heat the liquid to room temperature gas, with a pressure resistance value of 4.5MPA.

(2) Nitrogen: Using liquid nitrogen, the pressure can reach 3.0MPA (flow rate: 1.0m3/min), the pressure resistance value of the high-pressure liquid bottle is 4.5MPA, and the liquid is heated to room temperature gas.

(3) Air: If high-pressure air is used for cutting, the air pressure is ≥1.2MP.

2.8 Preparing tools

|

No |

Title |

Specification |

Quantity |

Remark |

|

1 |

Air control switch |

4P/AC380V/100A |

1 |

Total power supply (single wire specification: 10-16 square wire 10 square 800 watts, 16 square 1500 watts) |

|

2 |

Air control switch |

4P/AC380V/20A |

1 |

Exhaust fan (optional, self-matching) |

|

3 |

Air control switch |

4P/AC220V/63A |

1 |

Total power supply for machine tool (6-10 square wire, 6 square 500 watts, 10 square 1500 watts) |

|

4 |

Air control switch |

4P/AC220V/63A |

1 |

Spare parts |

|

5 |

Voltage stabilizer |

SBW-/20KVA/30KVA;AC30V |

1 |

|

|

6 |

Air compressor |

Output pressure≥1.2Mpa |

1 |

Need to remove oil and water |

|

7 |

Dryer |

With high-precision oil-water separator, copper plating 0.5MM thick |

1 |

If the machine configures an air compressor |

|

8 |

Ground needle |

2 meters long and 20mm diameter |

2 |

For machine and laser generator |

|

9 |

Vaporizer |

1 cubic meter/minute, withstand voltage 4.0MPA |

|

For liquid nitrogen and liquid oxygen |

|

10 |

Oxygen pressure reducing valve |

452X-175 |

1 |

Input≥15MPa Output:0.05~1.2MPa |

|

11 |

Nitrogen pressure reducing valve |

452IN-450-H |

1 |

Input≥15MPa Output:0.21-3.0MPa |

|

12 |

Distilled water |

|

120L |

For water cooling machine |

|

13 |

Nitrogen |

Purity≥99.995% |

1 |

|

|

14 |

Oxygen |

Purity≥99.995% |

1 |