What is the difference between pickled plate, cold rolled plate and hot rolled plate?

The pickling plate, cold-rolled plate, and hot-rolled plate exhibit significant differences in terms of manufacturing process, surface characteristics, and mechanical properties. The pickling plate is suitable for applications requiring smooth surfaces and improved chemical properties. The cold-rolled plate is ideal for high-strength and precision-sized products, while the hot-rolled plate is suitable for applications requiring toughness and high workability. Selecting the appropriate type of plate according to specific product requirements is crucial in practical applications.

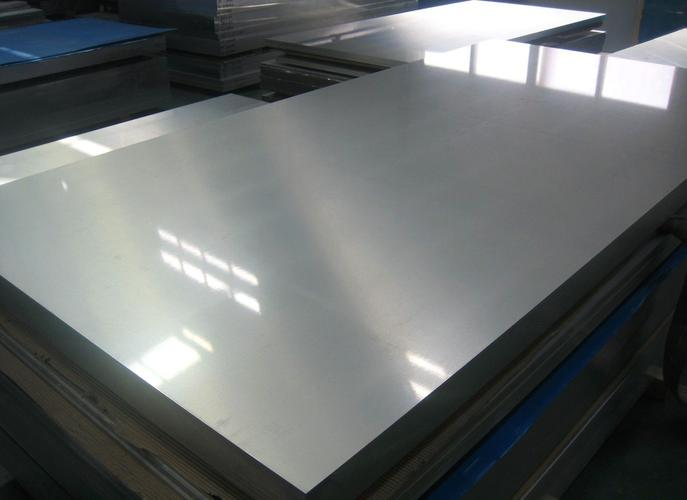

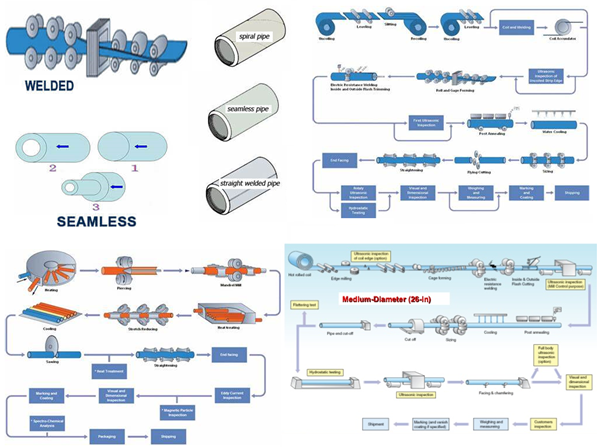

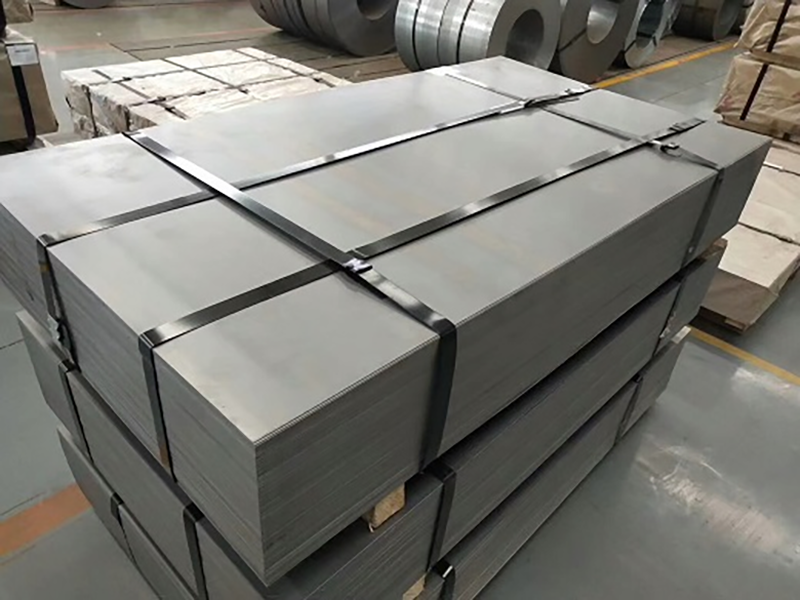

Cold-Rolled Plate: The cold-rolled plate is obtained by continuously rolling steel billets at room temperature through a rolling mill. The cold rolling process results in plastic deformation of the steel at room temperature, reducing thickness, increasing hardness, and improving surface smoothness.

Hot-Rolled Plate: The hot-rolled plate is obtained by heating steel billets to high temperatures (typically around 1100°C to 1250°C) and then continuously rolling them on a rolling mill. The hot rolling process increases the plasticity of the steel billets, making them easier to shape and press, but may result in a slightly rougher surface.

Surface Characteristics:

Pickling Plate: The pickling plate has a very smooth surface, and after the acid treatment, it exhibits high surface quality due to the removal of oxide layers and impurities. This makes the pickling plate widely used in applications with high surface requirements.

Cold-Rolled Plate: The surface of the cold-rolled plate is also very smooth, and after cold rolling, it exhibits good flatness and dimensional accuracy, making it suitable for products with high aesthetic requirements.

Hot-Rolled Plate: The surface of the hot-rolled plate is relatively rough due to the high-temperature rolling process, which may result in some oxide scale and scars. Therefore, hot-rolled plates are suitable for products with lower surface requirements and often undergo subsequent pickling or leveling processes.

Mechanical Properties:

Pickling Plate: The pickling plate exhibits good mechanical properties, with the acid treatment improving its hardness, strength, and toughness. This makes the pickling plate suitable for applications with high material performance requirements.

Cold-Rolled Plate: The cold-rolled plate maintains high hardness and strength due to the cold rolling process, exhibiting good strength and toughness. This makes the cold-rolled plate perform well in manufacturing high-strength and precision-sized products.

Hot-Rolled Plate: The hot-rolled plate exhibits relatively good toughness, making it suitable for applications requiring good workability. In some cases where forming processes are required, the hot-rolled plate is often a preferred choice.

In practical applications, it is crucial to select the appropriate type of plate according to specific product requirements. Each type of plate has its own suitable applications, and understanding their characteristics and advantages can help in making informed material choices to meet product design and production needs.

Expansion Information:

Applications of Pickling Plate: The pickling plate is widely used in automotive manufacturing, electrical appliance manufacturing, construction, and furniture industries. In automotive manufacturing, pickling plates are used to manufacture car body structures, doors, and roofs, where flatness and surface quality are crucial. In electrical appliance manufacturing, pickling plates are used to manufacture household appliances, kitchenware, and air conditioning casings, requiring high surface smoothness and corrosion resistance. Additionally, pickling plates are commonly used in the construction industry for high-surface-quality building facades and decorative panels.

Applications of Cold-Rolled Plate: Cold-rolled plates are widely used in automotive, electronics, aerospace, and construction industries. In the automotive industry, cold-rolled plates are used to manufacture car bodies, chassis, and automotive components, providing high strength and excellent formability for safer and more energy-efficient vehicles. In the electronics field, cold-rolled plates are used to manufacture computer, mobile phone, and home appliance casings, requiring high flatness and dimensional accuracy. In the aerospace industry, cold-rolled plates are used to manufacture aircraft components, where high strength and lightweight properties are crucial. Additionally, cold-rolled plates are used in the construction industry for steel structures and pipelines.

Applications of Hot-Rolled Plate: Hot-rolled plates are widely used in the steel, shipbuilding, petrochemical, and construction industries. In the steel industry, hot-rolled plates are used as raw materials for producing other plates (such as cold-rolled plates and galvanized plates) and are commonly used in bridges, railway tracks, and construction machinery. In shipbuilding, hot-rolled plates are used to manufacture ship hulls and decks, providing high toughness and malleability to withstand complex marine environments. In the petrochemical industry, hot-rolled plates are used to manufacture chemical equipment and containers, offering corrosion resistance and high-temperature resistance. In the construction industry, hot-rolled plates are used to manufacture steel structures and building materials such as beams, columns, and floor slabs.

In conclusion, pickling plates, cold-rolled plates, and hot-rolled plates play important roles in various fields and industries. Each type of plate has specific advantages and application scenarios, and selecting the appropriate type of plate according to specific requirements can enhance product quality and performance. Understanding their application areas and characteristics can help in better utilizing these plates.