Seamless Pipe vs Welded Pipe: Which is the Better Choice for Your Project?

When it comes to choosing the right type of pipe for your project, the decision between seamless and welded pipes can be a crucial one. Both seamless and welded pipes have their own set of advantages and disadvantages, and understanding the differences between the two can help you make an informed decision. In this blog, we will explore the key differences between seamless and welded pipes and discuss which option may be the better choice for your specific needs.

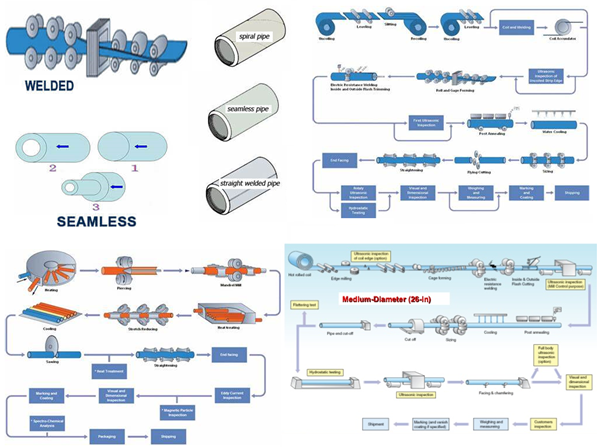

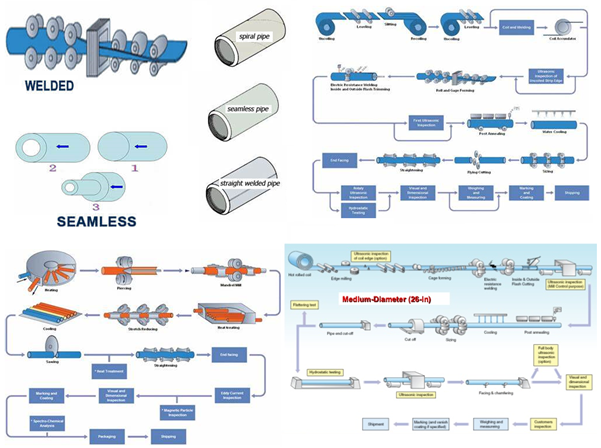

Seamless pipes are manufactured without any welding or joining process, resulting in a smooth and uniform surface. This manufacturing process involves the use of solid steel billets that are heated and extruded to form the seamless pipe. On the other hand, welded pipes are manufactured by welding or joining steel plates or coils together to form the pipe. This welding process can result in a visible seam along the length of the pipe.

One of the primary advantages of seamless pipes is their superior strength and reliability. Since seamless pipes are formed from a single piece of steel, they are inherently stronger and more resistant to pressure and stress. This makes seamless pipes an ideal choice for high-pressure applications such as oil and gas pipelines, where the integrity of the pipe is crucial. Additionally, seamless pipes are less prone to corrosion and are better suited for environments with high temperatures and corrosive substances.

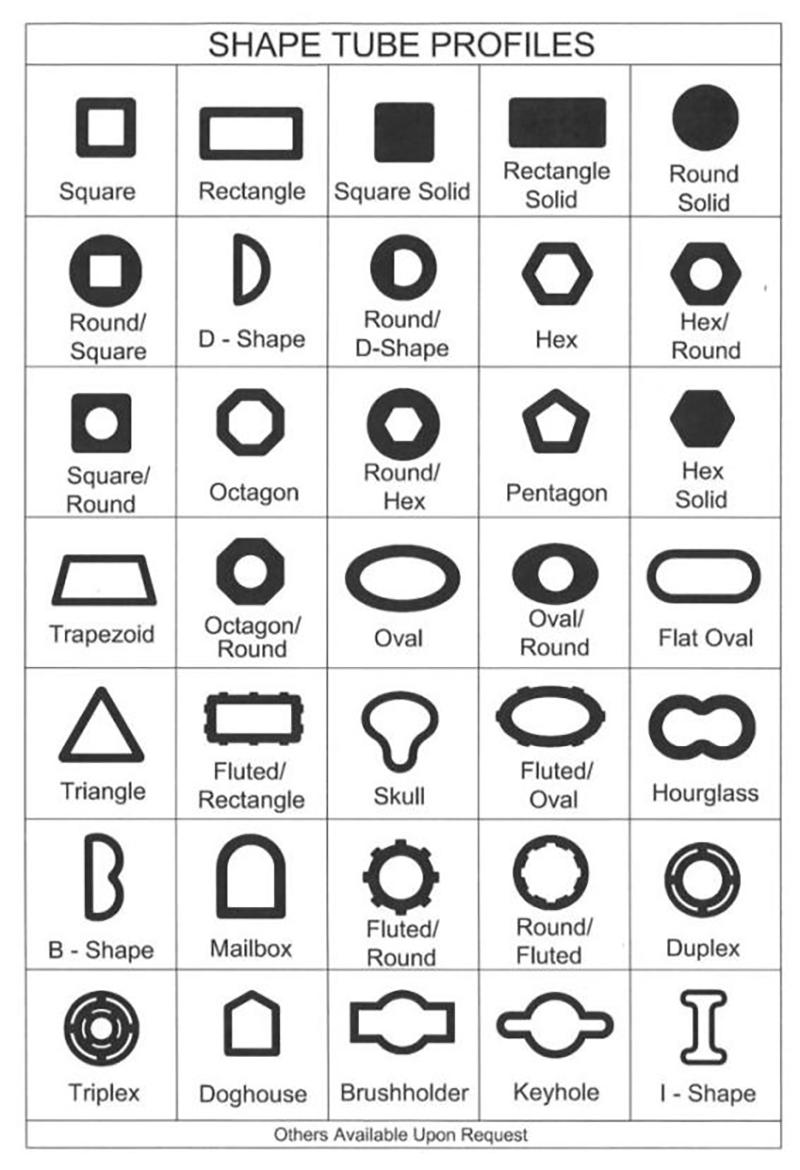

Welded pipes, on the other hand, are known for their cost-effectiveness and versatility. The welding process allows for a wide range of sizes and shapes to be produced, making welded pipes suitable for a variety of applications. Welded pipes are also easier to manufacture in large quantities, making them a more economical choice for projects with a high volume of piping requirements. However, the presence of the weld seam can make welded pipes more susceptible to corrosion and stress cracking, particularly in high-pressure or high-temperature environments.

In terms of performance, seamless pipes are often preferred for critical applications where strength and reliability are paramount. The absence of a weld seam eliminates the risk of weak points in the pipe, making seamless pipes a safer and more durable option for demanding conditions. On the other hand, welded pipes are well-suited for less demanding applications where cost and availability are the primary considerations. The versatility of welded pipes makes them a practical choice for a wide range of industries and projects.

Ultimately, the choice between seamless and welded pipes will depend on the specific requirements of your project. If strength, reliability, and resistance to corrosion are your top priorities, seamless pipes may be the better choice. However, if cost-effectiveness and versatility are more important, welded pipes may be the more suitable option. It is essential to carefully evaluate the needs of your project and consider the advantages and limitations of each type of pipe before making a decision.

In conclusion, the choice between seamless and welded pipes is a critical one that can significantly impact the performance and longevity of your piping system. By understanding the differences between the two options and considering the specific requirements of your project, you can make an informed decision that will ensure the success of your piping infrastructure. Whether you opt for the superior strength of seamless pipes or the cost-effectiveness of welded pipes, choosing the right type of pipe is essential for the long-term success of your project.