0102030405

How to cut special-shaped metal pipes?

2024-06-27 14:11:14

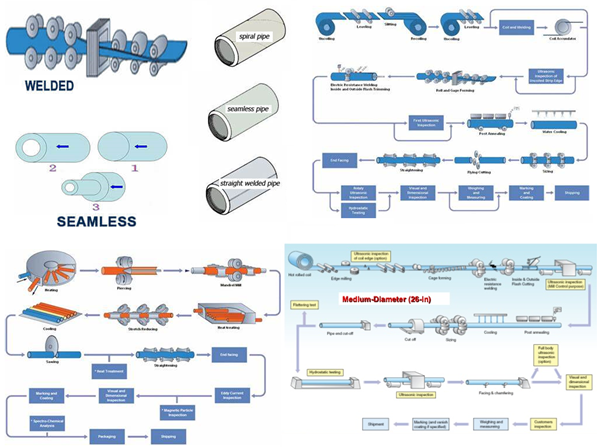

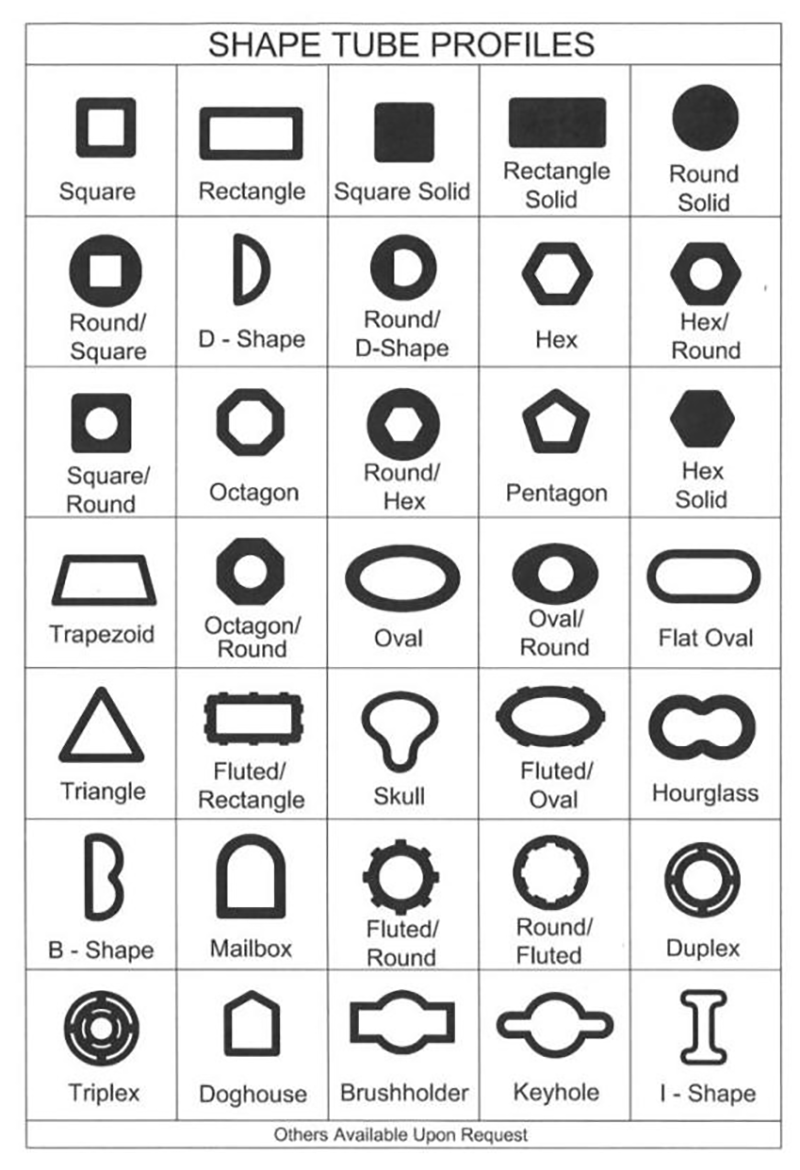

Special-shaped tubes are various types of seamless steel tubes produced through cold drawing. These tubes are generally classified based on their cross-sectional shapes and can be further categorized into seamless steel tube special-shaped tubes, aluminum alloy special-shaped tubes, and plastic special-shaped tubes based on the materials used. In this article, we will focus on the processing of seamless steel tube special-shaped tubes and aluminum alloy special-shaped tubes.

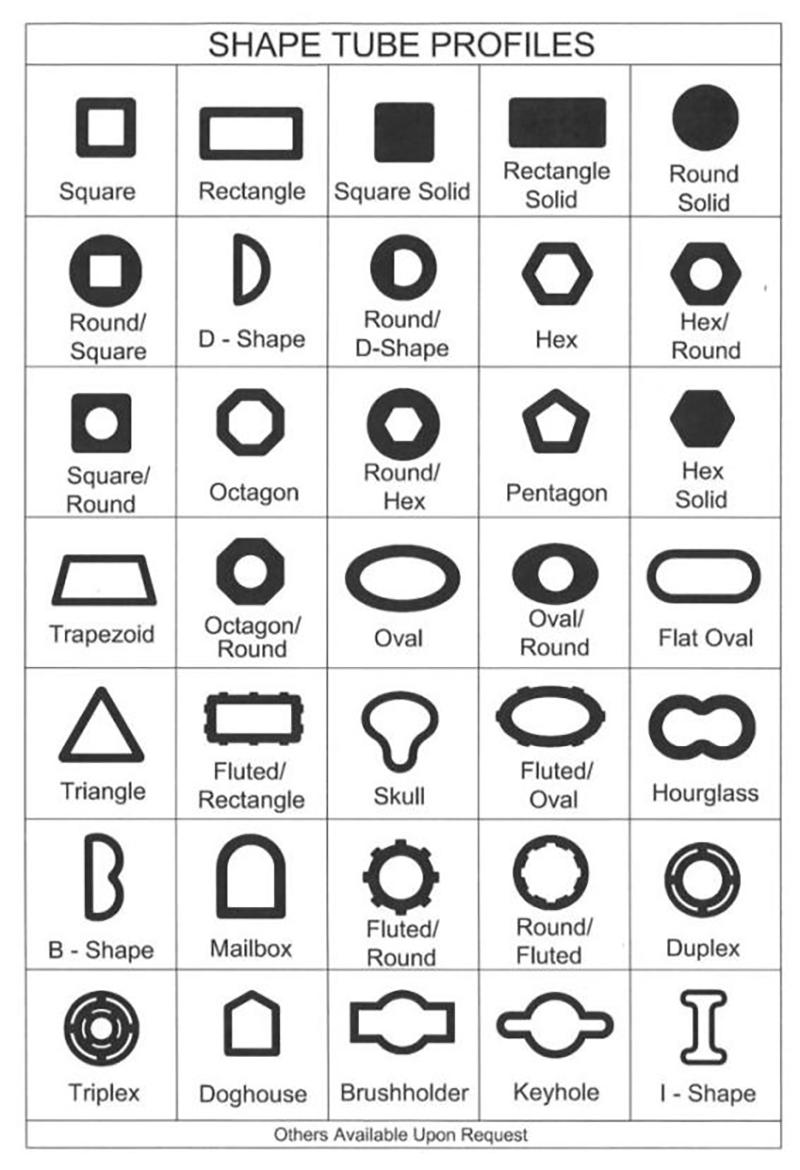

Special-shaped seamless steel tubes are widely used in various structural components, tools, and mechanical parts. Compared to round tubes, special-shaped tubes generally have larger moments of inertia and section moduli, providing greater resistance to bending and torsion. This capability significantly reduces the weight of structures and conserves steel. As shown in the diagram, our special-shaped tubes come in various shapes, with some having consistent wall thickness while others have varying wall thickness. Currently, our laser cutting machine is primarily used for special-shaped tubes with uniform wall thickness.

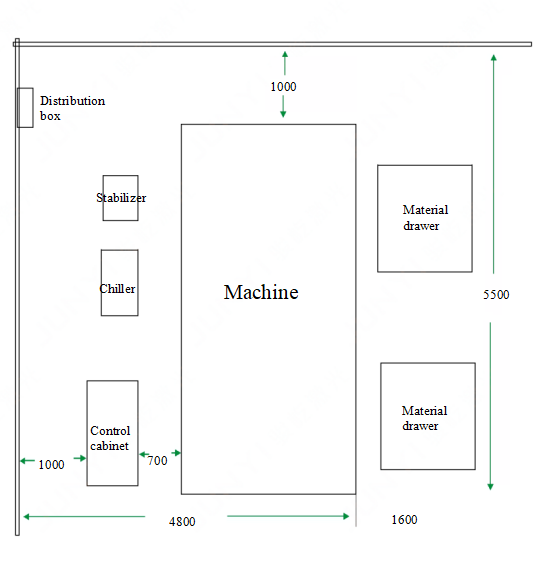

When using the laser cutting machine to cut special-shaped tubes, nesting software is required in the system. This nesting software is designed for the CYPCUT CypTube/TubePro tube cutting software and enables functions such as drawing processing, common edge nesting, weld seam compensation, and part drawing.

TubesT supports nesting of single or multiple parts to minimize material waste. It can handle common edge processing for parts with weld seam compensation and can also perform island common edge processing for identical or different parts, achieving precise common edges and reducing cutting times and costs. TubesT can automatically identify the stretching direction of IGS files and batch import various IGS files with different cross-sections. It supports the import of assembly files, significantly improving the efficiency of file imports. For common issues in tube cutting, such as perforation accuracy requirements and interference prevention during tube splicing, TubesT provides various graphic processing methods for users, simplifying and accelerating drawing processing. All tubes, including special-shaped tubes, can achieve automatic sorting of empty travel paths. For common rectangular and round tubes, it offers two automatic sorting strategies based on surface and circumference, achieving more rational processing paths. It also supports the extraction and editing of tool paths for special steel profiles such as angle steel, channel steel, and I-beams, and can perform common edge nesting for special steel profiles, greatly expanding the processing capabilities of tube cutting equipment. TubesT comes with 3D drawing functions, allowing even users with no 3D drawing experience to quickly adapt and easily perform stretching, perforation, cutting, V-grooving, and other operations.

By utilizing this nesting software, we can achieve cutting and engraving of different special-shaped tubes and efficiently address processing efficiency issues. We can provide solutions for semi-automatic and fully automatic tube cutting machines to solve customer processing speed concerns.

In conclusion, special-shaped tubes play a crucial role in various industries, and the use of advanced technology and software solutions enhances their processing capabilities, ultimately benefiting customers in terms of efficiency and quality.